Recommend Products

Shaft ultrasonic flaw detection

Shaft ultrasonic flaw detection can be applied to multi-size products, stepped shafts, slender shafts, automotive parts, forged gear shafts, laser-welded gears, etc.

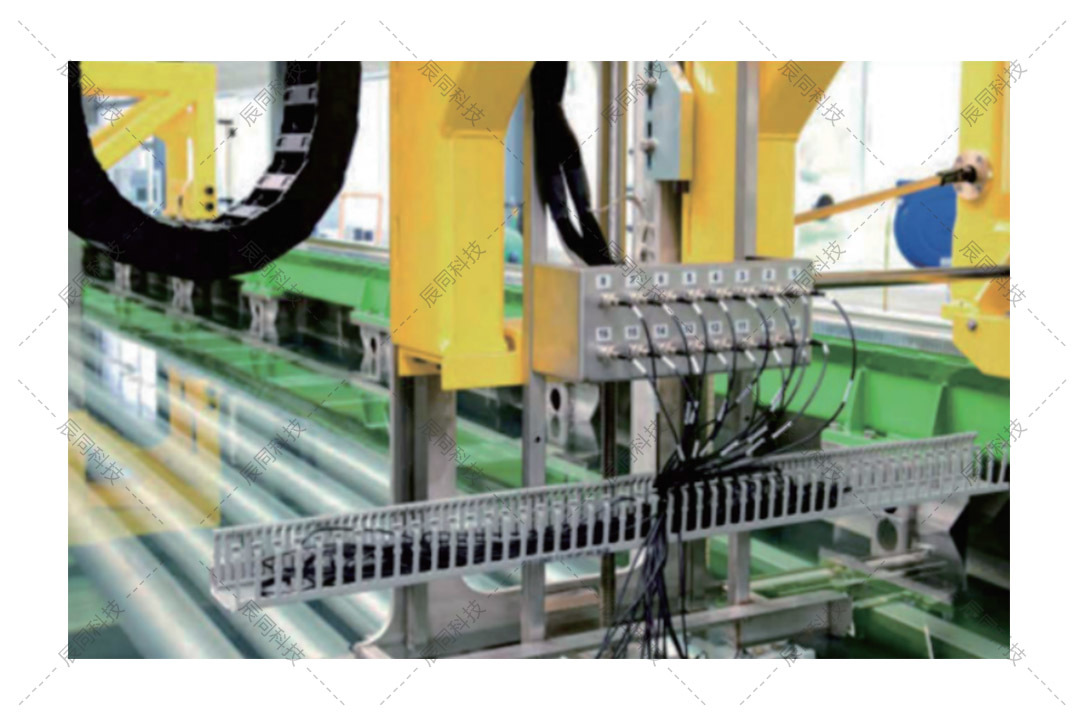

Automatic pipe water immersion ultrasonic flaw detection equipment CTT125

CTT125 is used in the field of ultrasonic nondestructive testing of petroleum pipelines with outer diameter ≥ 80mm, with customized development of ultrasonic inspection probes and integrated automation and intelligent technology, which greatly reduces the input of flaw detection personnel and production personnel, completely avoids human detection errors, realizes zero leakage detection and guarantees product safety.

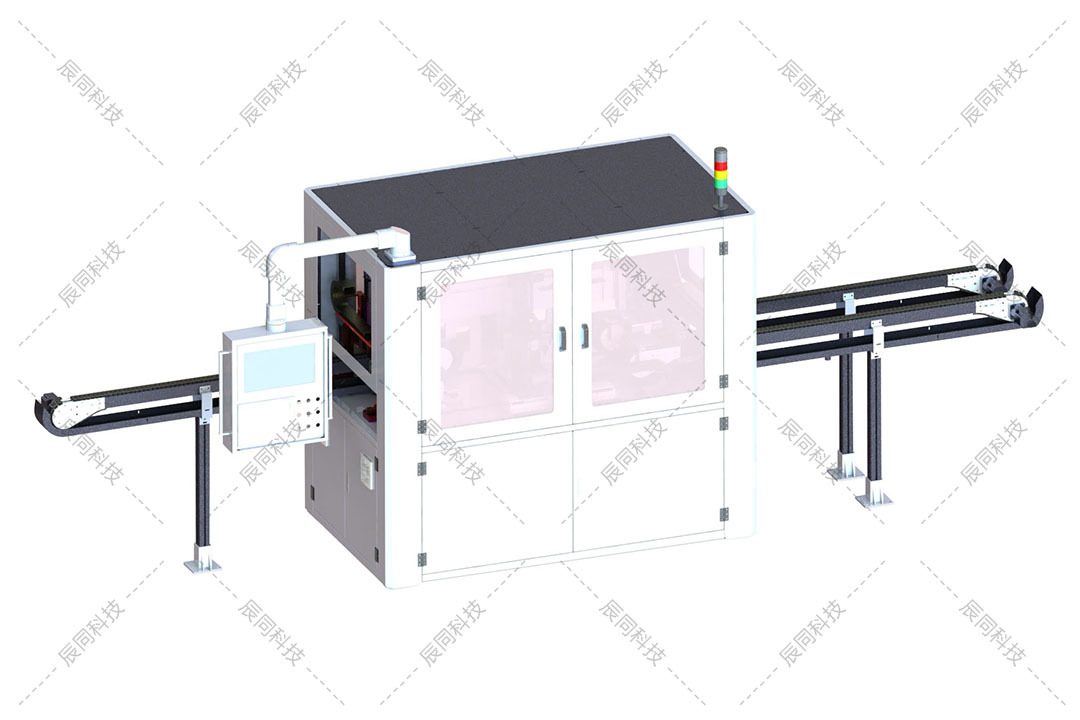

Automatic plate water immersion ultrasonic flaw detection equipment CTP4020

CTP4020 is used for ultrasonic inspection of large-size metal plates, custom-developed ultrasonic inspection probes, and integrated automation and intelligent technology, greatly reducing the input of flaw detection personnel and production personnel, completely avoiding human detection errors, achieving zero leakage, and ensuring product safety.

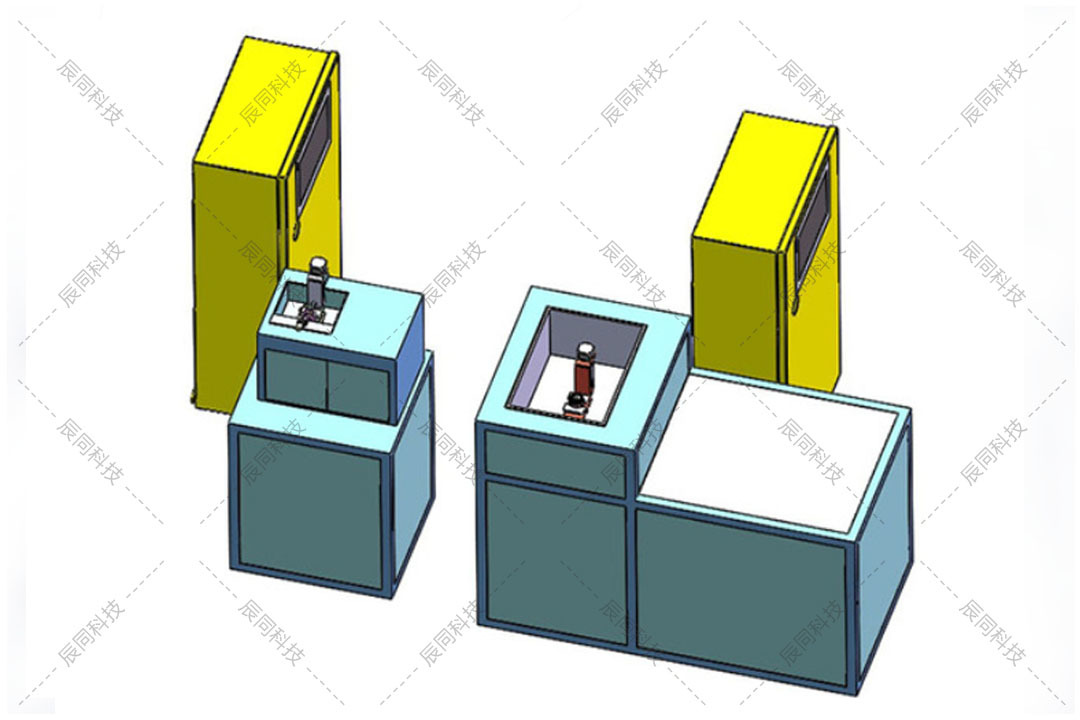

Large-scale liquid immersion ultrasonic testing equipment

Large scale ultrasonic testing equipment, using modular control probes to adapt to different specifications of parts. The detection sensitivity is FBH Φ 0.8mm. There are also oblique probes for detecting near surface defects, and the detection system uses multiple probes. The probe control is fully automatic for adjustment.

With soft protective film probe, W-type protective film

The main products are ultrasonic inspection instruments, magnetic particle inspection instruments, visual inspection equipment, bearing industry equipment, product functions cover internal defect detection of metal parts, external defect detection, product size detection, appearance inspection, automated assembly, intelligent storage and logistics and many other industrial applications.

With hard protective film probe, H/HB type protective film

The main products are ultrasonic inspection instruments, magnetic particle inspection instruments, visual inspection equipment, bearing industry equipment, product functions cover internal defect detection of metal parts, external defect detection, product size detection, appearance inspection, automated assembly, intelligent storage and logistics and many other industrial applications.