Recommend Products

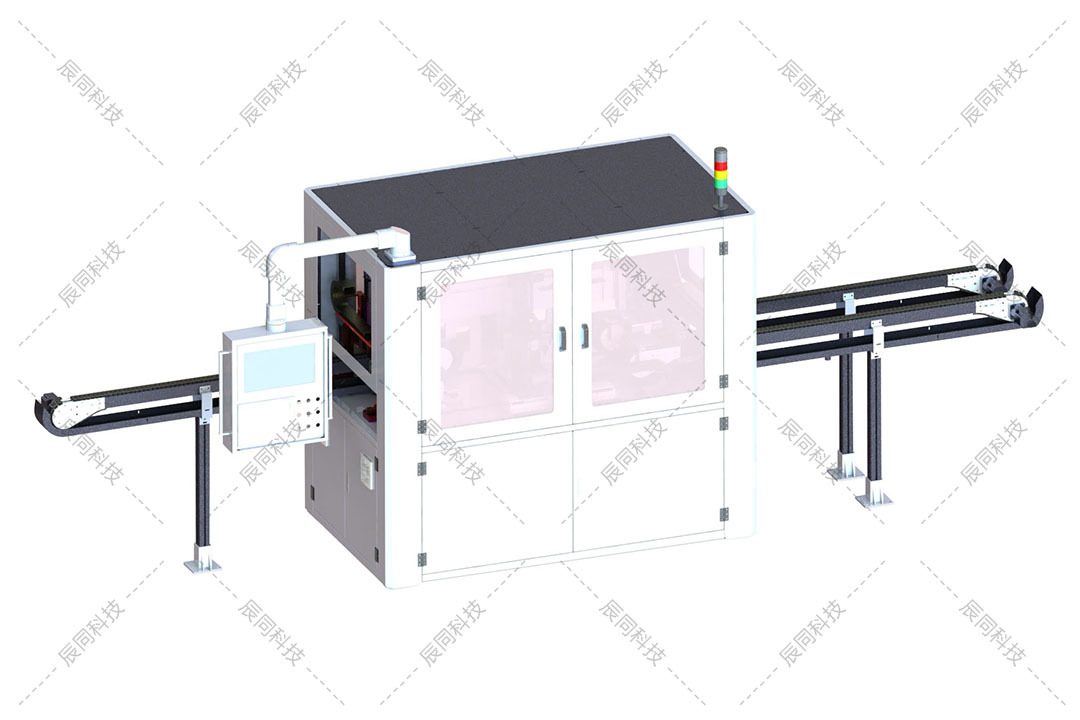

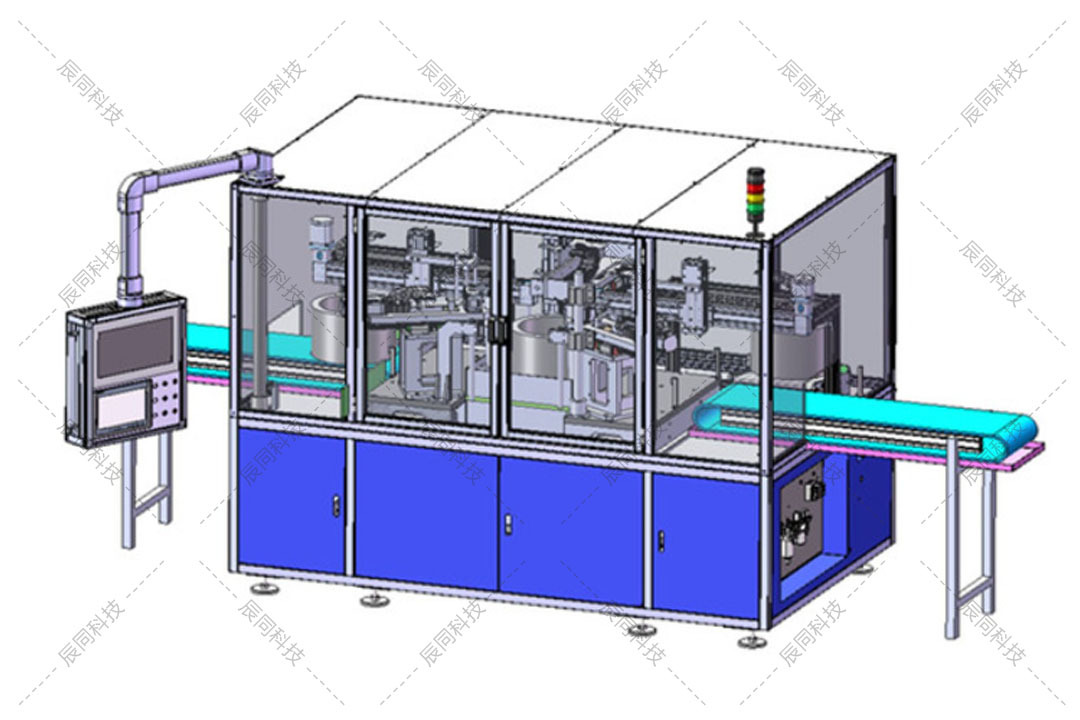

Steel ball automatic liquid immersion ultrasonic flaw detection equipment CTB4090-4

CTB4090-4 is used to inspect wind power steel balls of Φ40-Φ90. This equipment provides unlimited possibilities for intelligent inspection and intelligent manufacturing of wind power steel ball production based on the realization of one-stop reporting functions such as fully automatic loading at multiple stations, online inspection and sorting, fully automatic discharging, online capacity statistics, online yield statistics, and optional MES access function.

Steel ball automatic Liquid immersion ultrasonic flaw detection equipment CTB4090-8

CTB4090-8 is used for inspecting Φ40-Φ90 wind power steel balls. This series of equipment provides unlimited possibilities for intelligent inspection and smart manufacturing of wind power steel ball production based on the realization of one-stop reporting functions such as multi-station automatic loading, online inspection and sorting, automatic discharging, online capacity statistics, online yield statistics, and optional MES access function.

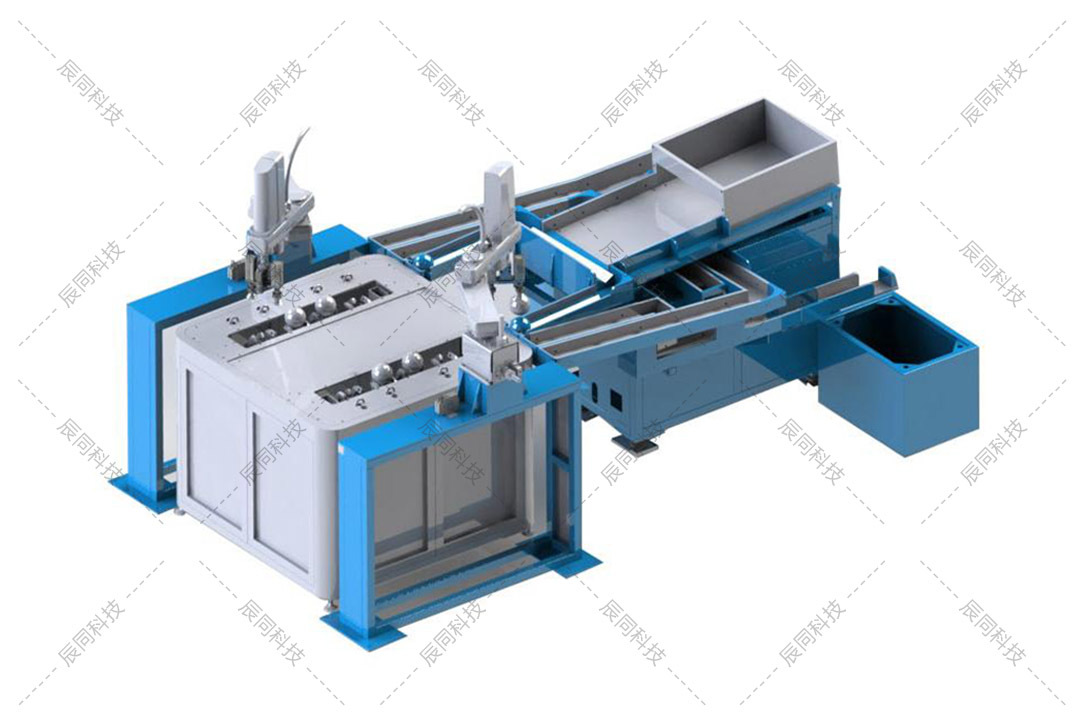

Small roller ultrasonic testing equipment CTH1030 CTH2050

The small roller ultrasonic testing equipment adopts robot controlled probes to adapt to different types of rollers (TRB/CRB). The detection sensitivity is FBH Φ 0.5 * 1.0mm. Additionally, oblique probes are used to detect near surface defects. The detection system uses two sets of probes. Adopting two parallel probe racks with dual probes. The probe control is fully automatic for adjustment.

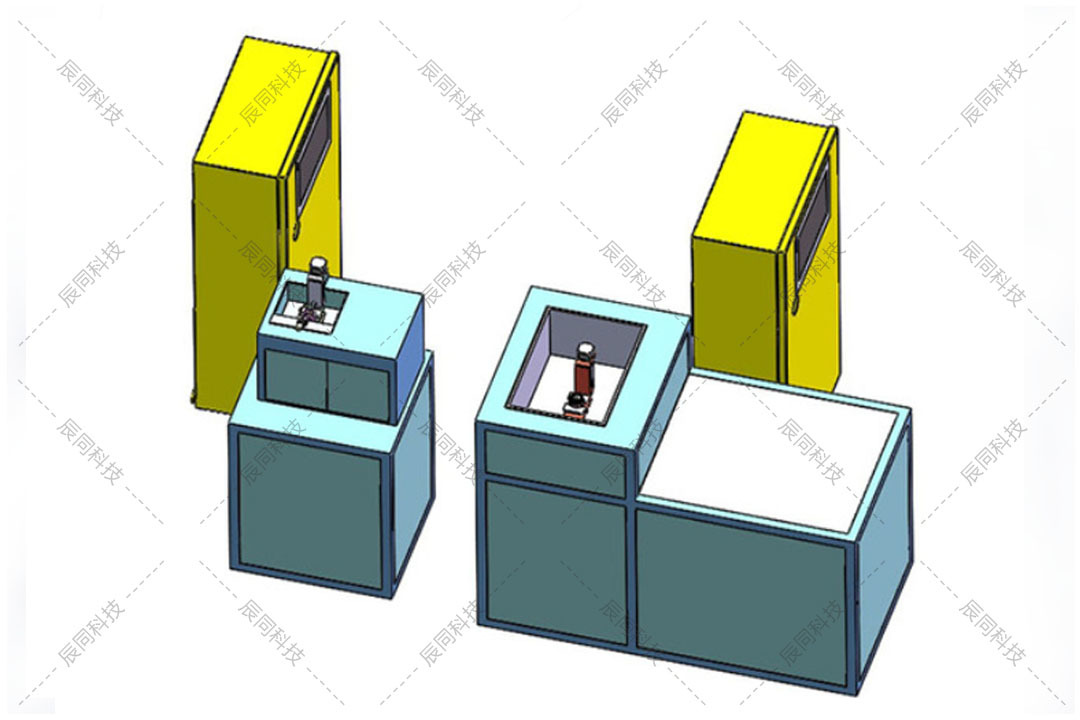

Bearing ring automatic liquid immersion ultrasonic flaw detection equipment CTR1236

CTR1235 is used to detect large wind power transmission bearing rings with an outer diameter of Φ120-Φ360, custom-developed ultrasonic detection probes, and integrated automation and intelligent technology, which greatly reduces the investment of inspection personnel and production personnel, completely avoids human detection errors, and achieves zero leakage Inspection to ensure product safety.

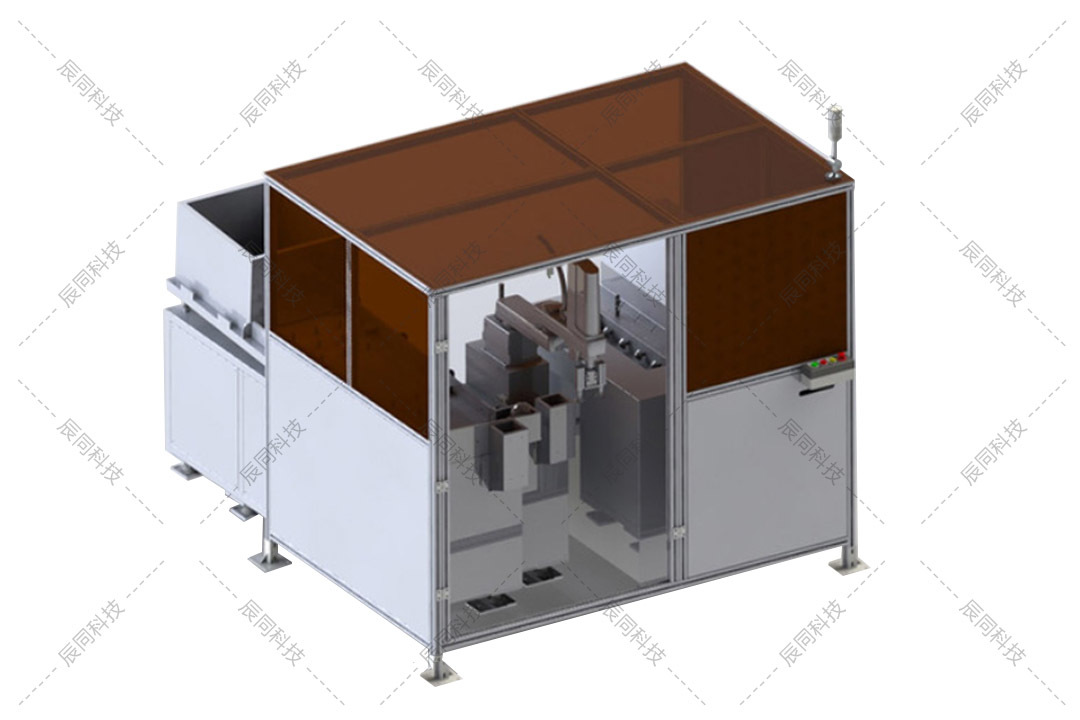

Automotive transmission gear automatic liquid immersion ultrasonic flaw detection equipment CTG0620

CTG0620 is used to inspect gearbox gears with outer diameter Φ60-Φ200, with customized development of ultrasonic inspection probes and integrated automation and intelligent technology, which can greatly reduce the input of inspection personnel and production personnel, completely avoid human detection errors, achieve zero leakage, and guarantee product safety.

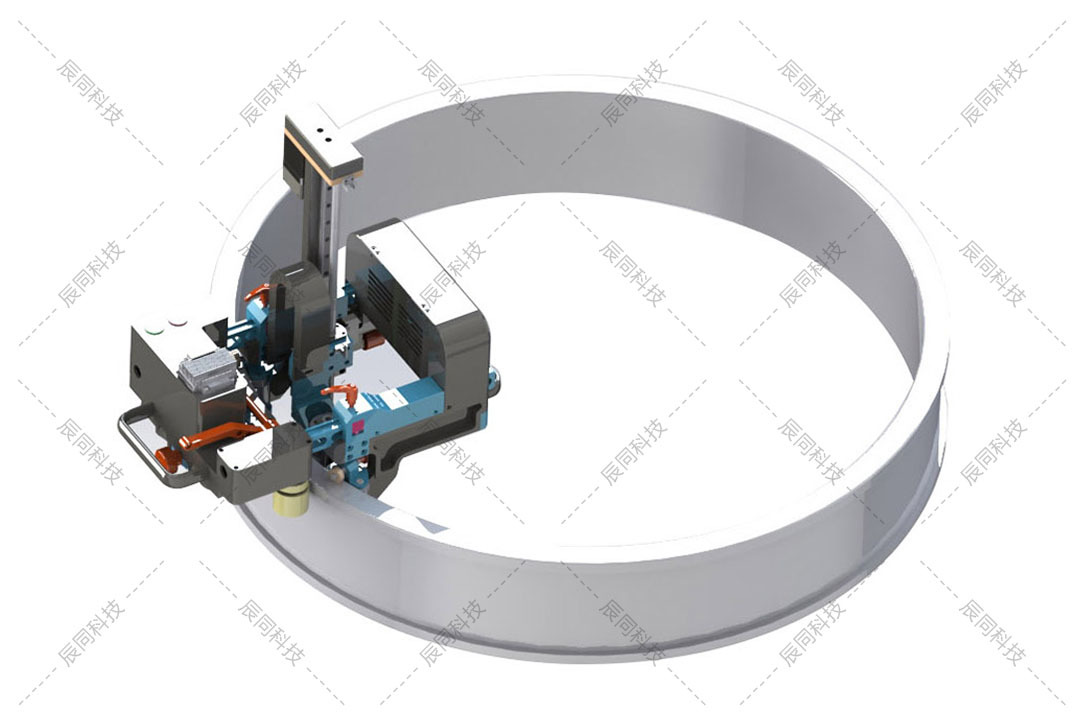

Automatic ring forging liquid immersion ultrasonic crawler CTS10

Bearing steel ring ultrasonic flaw detection crawler is suitable for rolling bearing ring of spherical, tapered and cylindrical bearings for ultrasonic inspection.