Application

Application of Ultrasonic Nondestructive Testing

Visual Applications

Liquid immersion ultrasonic flaw detector

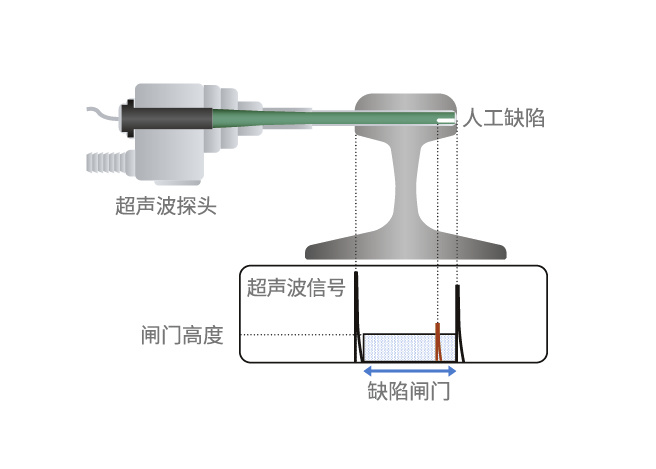

The generation of ultrasonic waves: The ultrasonic transmitter (probe) used in ultrasonic testing uses piezoelectric materials to generate ultrasonic waves through the voltage changes of the piezoelectric materials. Through voltage pulses, piezoelectric materials generate vibrations, and the sound waves generated by the vibrations are propagated into the workpiece (inverse piezoelectric effect).

Ultrasound reception: In most cases, the same probe is used for both emission and reception. The reflected waves from the workpiece interface or internal defects can also be received by the probe. Sound wave pulses generate voltage and pressure loads on piezoelectric materials, which are then converted into electronic voltage (positive piezoelectric effect).

All mechanical and electrical control systems, as well as testing software systems of the fully automatic ultrasonic testing system, are independently designed, produced, and manufactured by Chentong Technology Company. The detection objects include pipelines, steel billets, plates, welds, pressure cylinders, bearings, vortex blades, aerospace workpieces, rollers, gas cylinders, etc.

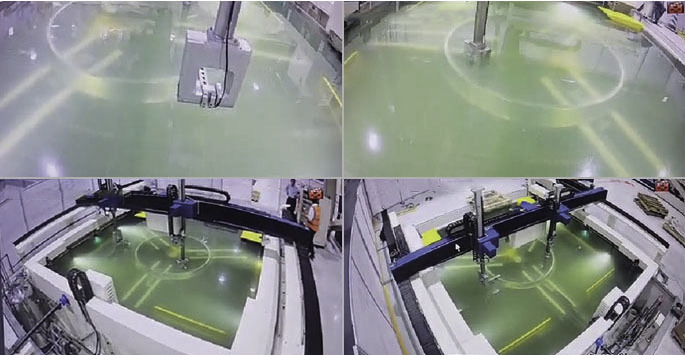

UT inspection of large environmental components

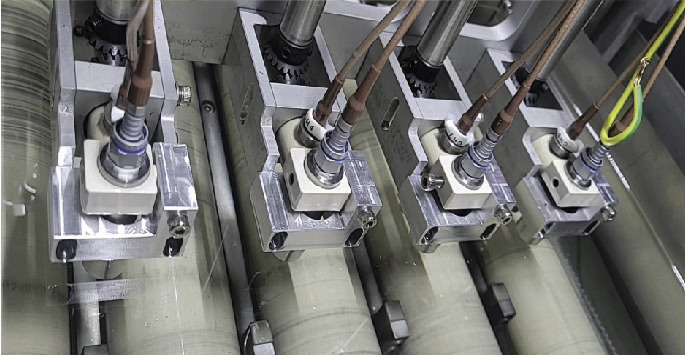

High speed roller UT detection

High speed roller UT detection

Real time monitoring of the detection process

Real time monitoring of the detection process

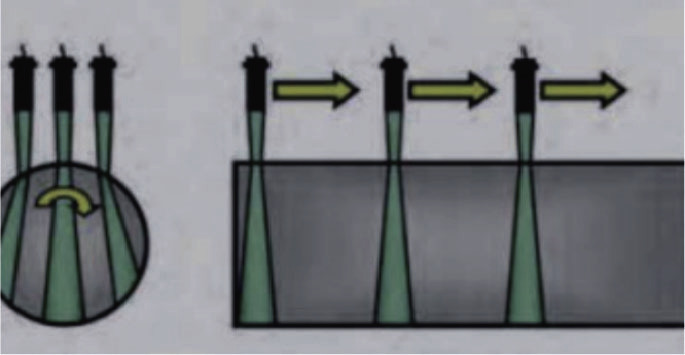

Using 3 straight probes and 6 oblique probes to detect aluminum alloy workpieces

Using 3 straight probes and 6 oblique probes to detect aluminum alloy workpieces

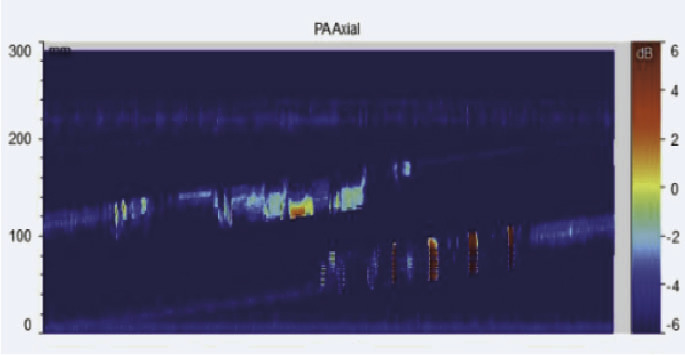

C-scan detection results with multiple statistical functions, flexible designation of "observation area"

C-scan detection results with multiple statistical functions, flexible designation of "observation area"

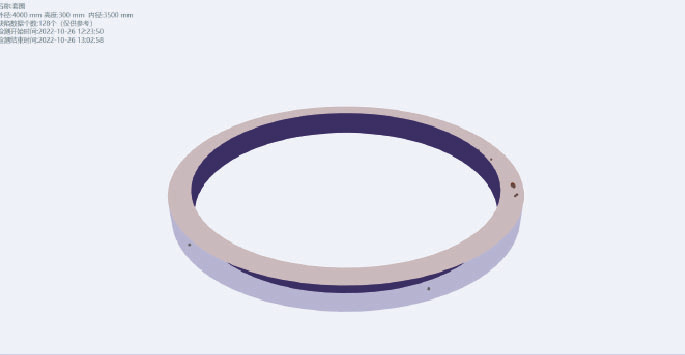

The 3D image of the ring ultrasonic testing can observe the location/depth of defects, which can be evaluated and can be customized

The 3D image of the ring ultrasonic testing can observe the location/depth of defects, which can be evaluated and can be customized