Recommend Products

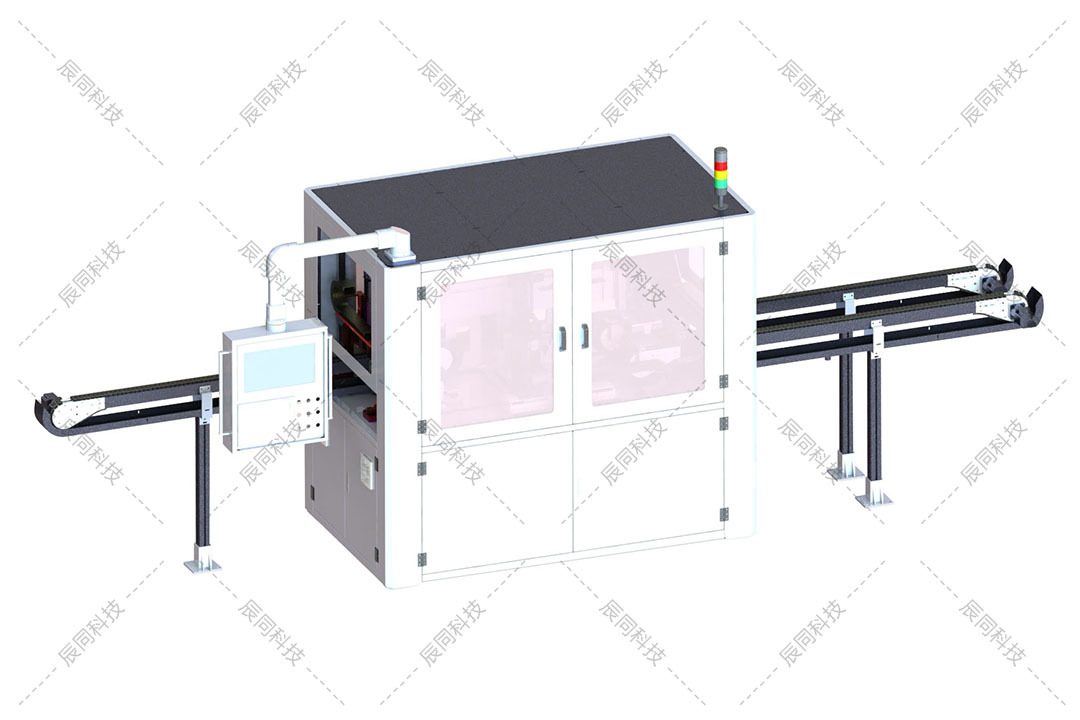

Ultrasonic testing equipment for large bearing rings CTR1840 CTR2560

Large scale bearing ring ultrasonic testing equipment with detection sensitivity FBH Φ 0.5 * 1.0mm as an artificial reference defect. The detection system uses one set of three probes. The probe control is fully automatic for adjustment. Analyze and evaluate defects by directly analyzing defect echoes or detecting the attenuation of bottom echoes.

Ultrasonic testing equipment for large bearing rings CTR3080

Large scale bearing ring ultrasonic testing equipment with detection sensitivity FBHΦ0.5 * 1.0mm as an artificial reference defect. The detection system adopts dual axis simultaneous detection, with 3 probes in each group. The probe control is fully automatic for adjustment. Analyze and evaluate defects by directly analyzing defect echoes or detecting the attenuation of bottom echoes.

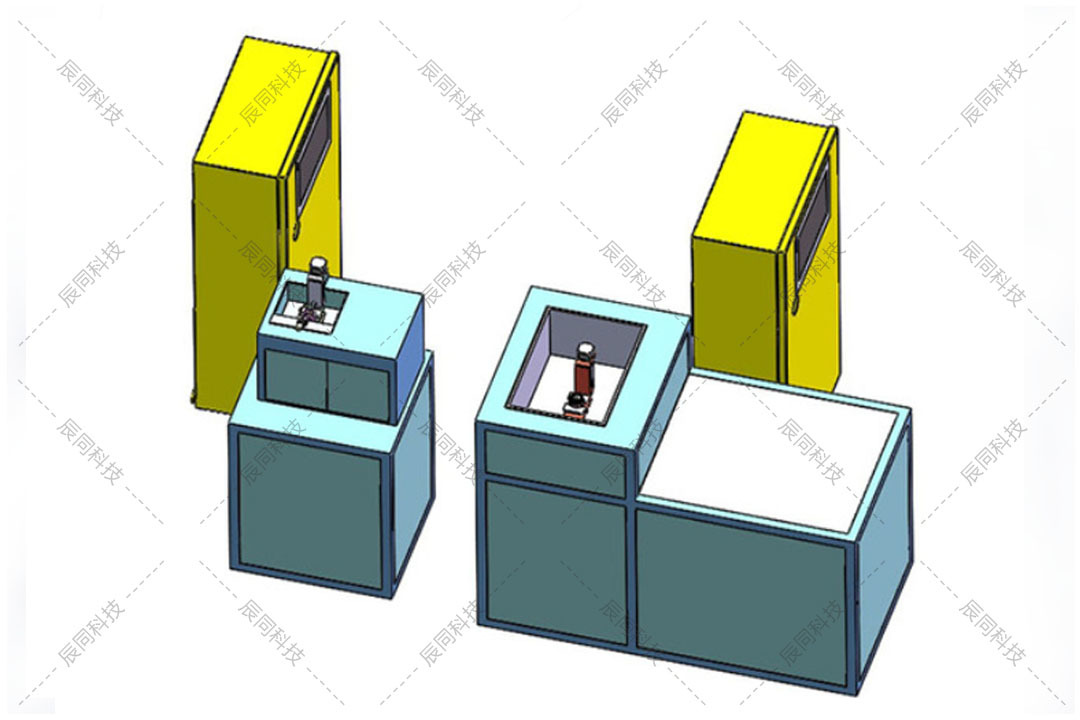

Ultrasonic testing equipment for medium-sized bearing rings

Medium sized bearing ring ultrasonic testing equipment with detection sensitivity FBH Φ 0.5 * 1.0mm as an artificial reference defect. The detection system uses one set of three probes. The probe control is fully automatic for adjustment. Analyze and evaluate defects by directly analyzing defect echoes or detecting the attenuation of bottom echoes.

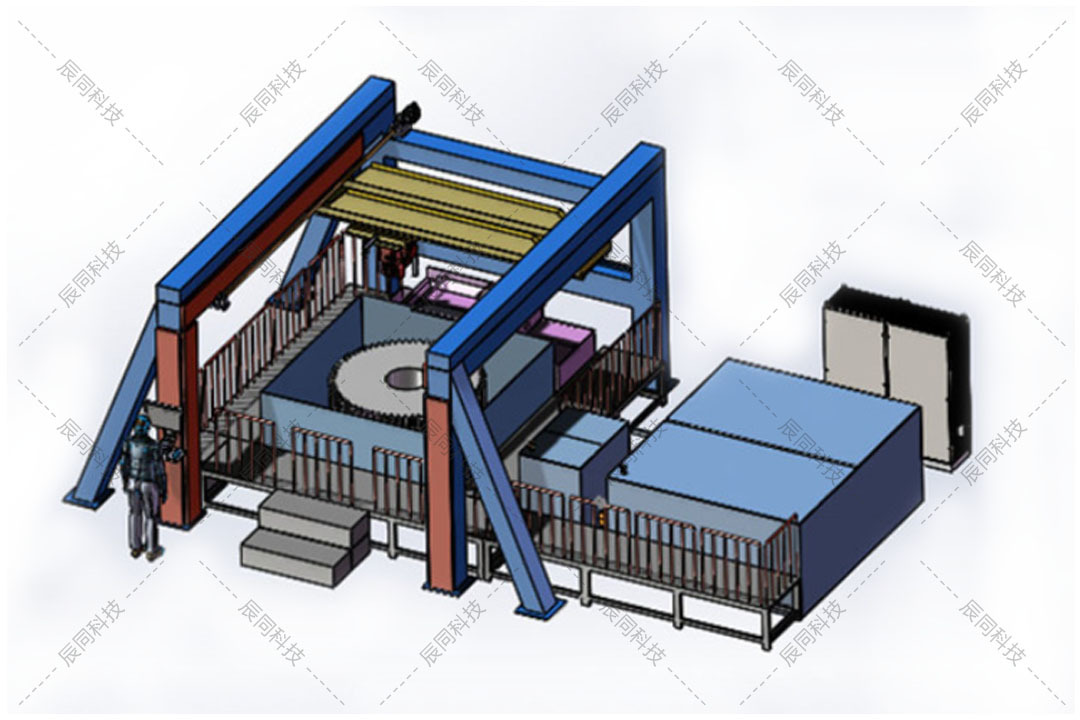

Gear ring automatic liquid immersion ultrasonic flaw detection equipment CTG0515

CTG0515 is used to inspect large wind power transmission gear ring with outer diameter Φ500-Φ1500, with customized development of ultrasonic inspection probe and integrated automation and intelligent technology, which can greatly reduce the input of inspection personnel and production personnel, completely avoid human detection errors, achieve zero leakage, and guarantee product safety.

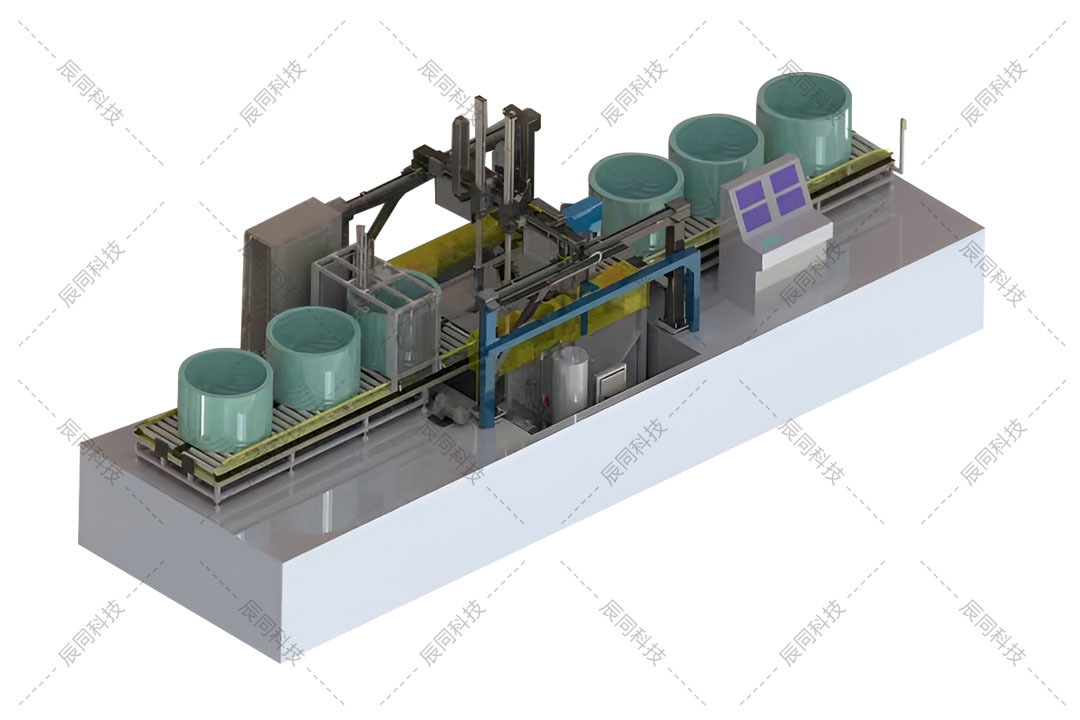

Bearing ring automatic liquid immersion ultrasonic flaw detection equipment CTR210

CTR210 is used to inspect large wind power drive shaft bearing ring with outer diameter Φ500-Φ1500. Customized development of ultrasonic inspection probe and integration of automation and intelligent technology can greatly reduce the input of flaw detection personnel and production personnel, completely avoid human detection errors, realize zero leakage detection and guarantee product safety.

Automatic liquid immersion ultrasonic flaw detection equipment CTR412CGB

CTR412CGB is used to inspect large wind turbine gearboxes with outer diameter Φ400-Φ1200. Customized development of ultrasonic inspection probes and integration of automation and intelligent technology can greatly reduce the input of inspection personnel and production personnel, completely avoid human detection errors, achieve zero leakage, and guarantee product safety.