Application areas

Nuclear power

Introduction

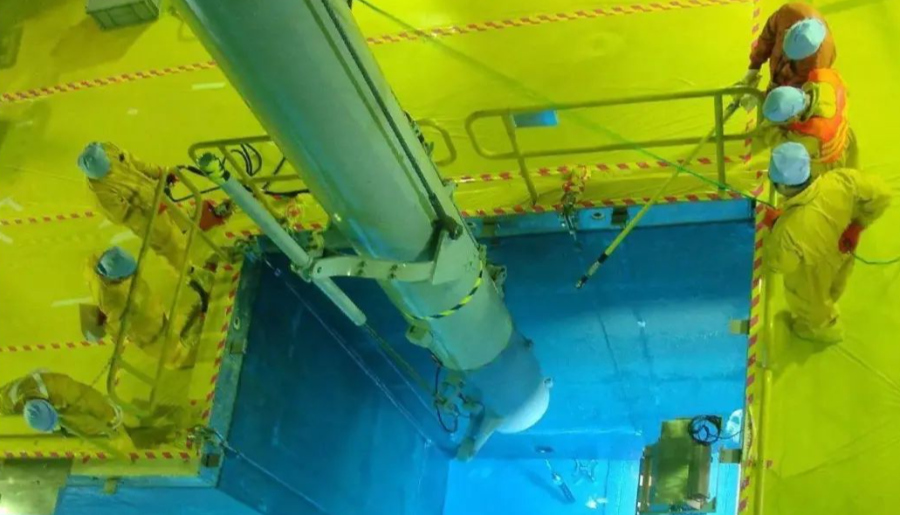

Nuclear power plant process pipelines require non-destructive testing before they are put into operation.

However, the large number of items in nuclear power plants and the small clearances of pipelines often result in inaccessible weld inspection due to interference from surrounding items, causing serious safety and quality hazards.

In some cases, concrete walls need to be removed to ensure sufficient space for weld access.

1. Introduction to the inspection method of non-destructive testing technology

The use of non-destructive testing technology to carry out inspection operations in the field of nuclear power is based on the premise of not damaging the performance of the object to be inspected, using the theory of physics, chemistry and materials as the basis for effective inspection of equipment components, mainly the external inspection of the equipment, the surface and appearance of the equipment to test, the volume of the equipment to test, etc..

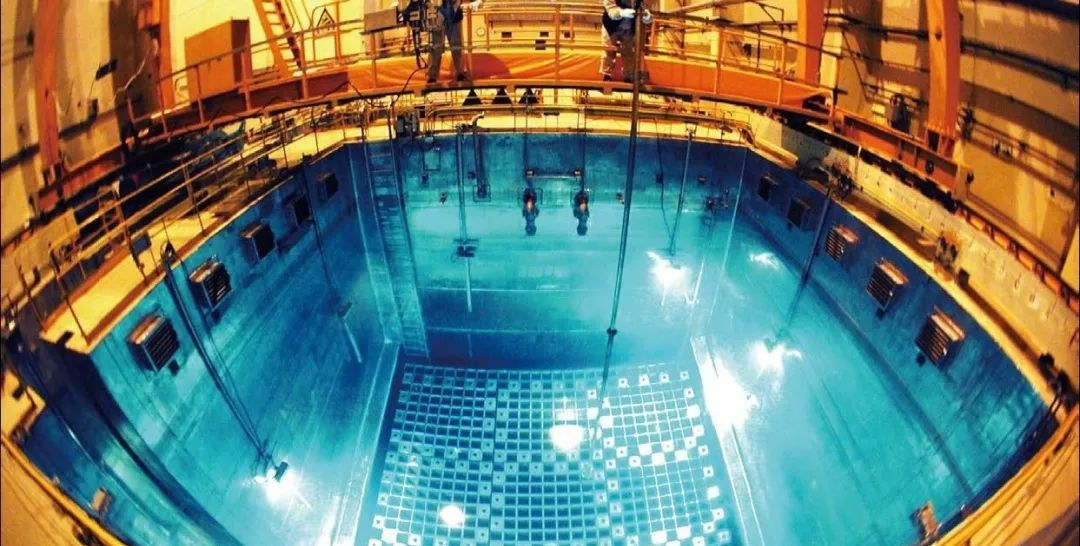

For inspection work in other areas, remote devices and remote control devices can be used for inspection.

For example, remote detection technology can be used to monitor environments with imitation radiation.

Remote inspection can be used to inspect the appearance.

For the inspection of the parts of the equipment to see the security of the small parts that make up the equipment, to see if the parts and equipment appear loose and damaged phenomenon, to see if the components appear loose and erosion phenomenon, to ensure the integrity of the equipment components.

For the inspection work of the surface, you can use magnetic powder to combine with liquid penetration to ensure that its permeability later to carry out the inspection work of the surface.

In monitoring, the environment that is easily accessible to personnel can be detected using remote detection methods and magnetic particle penetration methods.

For the staff is not easy to approach the area, for the volume of the detection can be used to detect the ultrasonic method, can achieve the goal of intelligent detection in the field of nuclear power.

Eddy current, a detection method, is mainly used to detect tubes that generate steam, and it can detect the thin thickness of the eroded tube wall, and detect the drawbacks caused by operational errors in the actual installation works, such as the detection of dents.

2. Clarify the content of non-destructive testing management

①Nondestructive testing personnel management

Strict management of non-destructive testing personnel qualification training and examination work, training "civilian nuclear safety equipment nondestructive testing personnel qualification management regulations" put management requirements and assessment of technical requirements for comprehensive study, familiar with the qualification coverage and scope of application, field operations as required, licensed qualifications within the standardized operations.

Dynamic management of qualifications, qualifications and the continuous maintenance of qualifications, personnel skills skilled to solve site specific flaw detection problems, to eliminate the fraudulent use of qualifications or over-qualification range of flaw detection and unlicensed work and other phenomena.

Need to strictly comply with the provisions of the Nuclear Safety Law, strictly prohibit the borrowing and operation of ray sources in different enterprises, and mixed use of ray sources.

② Inspection culture of nondestructive testing

Strictly implement "0 tolerance for non-compliance", "0 tolerance for falsification", "0 tolerance for concealment and misrepresentation", to achieve graded organization, each responsible for;

Full participation, highlighting the focus of welding management, analysis of welding cases, acceptance of lessons learned and experience feedback, establishment of rules and regulations, continuous improvement and enhancement, one-time welding success, quality assurance and prevention of rework.

Quality assurance and testing responsibility culture needs to focus on the improvement of the non-destructive testing system and familiarity with technical standards, especially for the inspection and acceptance standards and compliance with the mandatory provisions of engineering construction, welding standards and non-destructive testing standards between the convergence of the standard unity, to eliminate the customary bad practices of testing personnel, strictly according to the requirements of the non-destructive testing process assessment process development and on-site testing, to do a full sampling ratio Coverage, "by a certain percentage of RT and 100% RT welding"

All need to pay equal attention to the good cultural atmosphere.

③ Nondestructive data management

Nondestructive testing data management, the need to focus on checking the welding control sheet and welding commissioning inspection control sheet and rework notice and nondestructive method of interface control.

For NCR, non-destructive testing report review, in the review of non-destructive reports should be fully combined with the manufacturer's RT negatives, reports and pre-service inspection units on the same part, the same weld RT report, in order to find the specific shape of the defect and the trend of defect distribution, for subsequent production for reference.

3. How to manage the non-destructive testing work

3.1 Standards of testing and personnel training and judging

In order to achieve the maximum application value of NDT technology, ensure the stability of the equipment and guarantee the safety of the actual operation of the equipment, it is necessary to meet certain testing standards when testing and installing the equipment.

For example, when using NDT technology for testing operations, you can learn the testing standards and requirements of Western frameworks.

For example, the U.S. ASME boiler and pressure vessel code, France issued the rules for the design and construction of nuclear island machinery and equipment, to ensure the normative and safety of NDT technology in the actual application process.

Second, in order to achieve the maximum effect of the application of non-destructive testing technology, the staff of the test should be judged and trained to ensure the correctness of the application of non-destructive testing technology.

For non-destructive testing staff, the skills and professional knowledge training, to ensure that they have the theoretical knowledge of testing, to ensure that they have good practical operation ability, to judge the work of non-destructive testing staff, according to the civil nuclear safety equipment non-destructive testing technology assessment - specifications and requirements, to examine and judge its testing work, to find its work deficiencies and shortcomings, to carry out targeted education and In the process of work, a reward and punishment system can be established to reward staff with good performance to stimulate their enthusiasm for work and increase their motivation for testing, and to warn staff with poor behavior to increase the standardization of their work behavior, and to set up internal examples and benchmarks to play a demonstration role to ensure the orderly development of testing work and to promote To set up internal examples and benchmarks to play an exemplary role to ensure the orderly development of testing work and promote the development of nuclear power industry.

3.2 Joint Inspection of NDT Laboratory Work

Focus on the inspection of the correct operation of the testing system, the consistency of the process and the results, specify the corresponding nondestructive testing methods and content, layering the correct application of visual inspection, weld size inspection, penetration inspection, vacuum leakage inspection, ultrasonic testing, ray testing, phased array testing, eddy current testing and other methods, with special attention to the full coverage of the proportion of random inspections of welders, especially the first weld of each welder Weld and sampling weld inspection, double inspection and full inspection when necessary, to verify the quality of welding.

Carry out quarterly joint inspection of welding, non-destructive testing quality, joint inspection of engineering entities and engineering data, quality issues look back, sampling and inspection of the main control dimensions of the weld according to the requirements of the mandatory provisions of the standard, especially the width, length and foot size of the weld to measure and check the compliance, the surface condition of the weld to check for porosity, slag, not fused, not welded through, biting edge The inspection and removal of defects such as pores, slag, unfused, unbroken, bitten edges;

Inspection of welding control sheets, including the inspection of the status of the welder's stamp number, weld markings, etc., review of the organization of welding records, review from time space and process logic, check the interface between welding and NDT records and reports to ensure that the quality is in a controlled state.

Conclusion

In summary, nondestructive testing technology plays an irreplaceable role in the field of nuclear power, in order to play the maximum effect of nondestructive testing technology, the staff in the actual inspection work, to ensure the scientific nature of the detection method of nondestructive testing technology, with remote monitoring methods and close contact methods, with ray and ultrasonic volume methods and magnetic particle penetration surface detection methods to monitor, to ensure that the main work of nondestructive testing technology Content perfection and diversity, classification and testing of different testing contents, standards for testing and personnel training and judging, ensuring the work motivation of testing staff, establishing a reward mechanism with clear rewards and penalties, increasing staff motivation, and ensuring the good development of monitoring work.

- End -

1 Attention:

The content involves standards may exist repealed, please do not use in practice, this article only provides knowledge reference ideas! If there are errors, please leave a message to correct, and hope that these knowledge points can help you!

2 Sources and statements:

Source of this article: Frontiers of Architecture Research, 2019, 15

This article is written by: Li Ziyang Wang Tengteng

Statement: The content of this article only represents the views of the author, not the position of this number, edited with a small amount of additions and deletions, and the content is only for technical communication and sharing, if there is any infringement, please contact us, we will promptly delete!