Recommend Products

Ultrasonic testing equipment for large bearing rings CTR3080

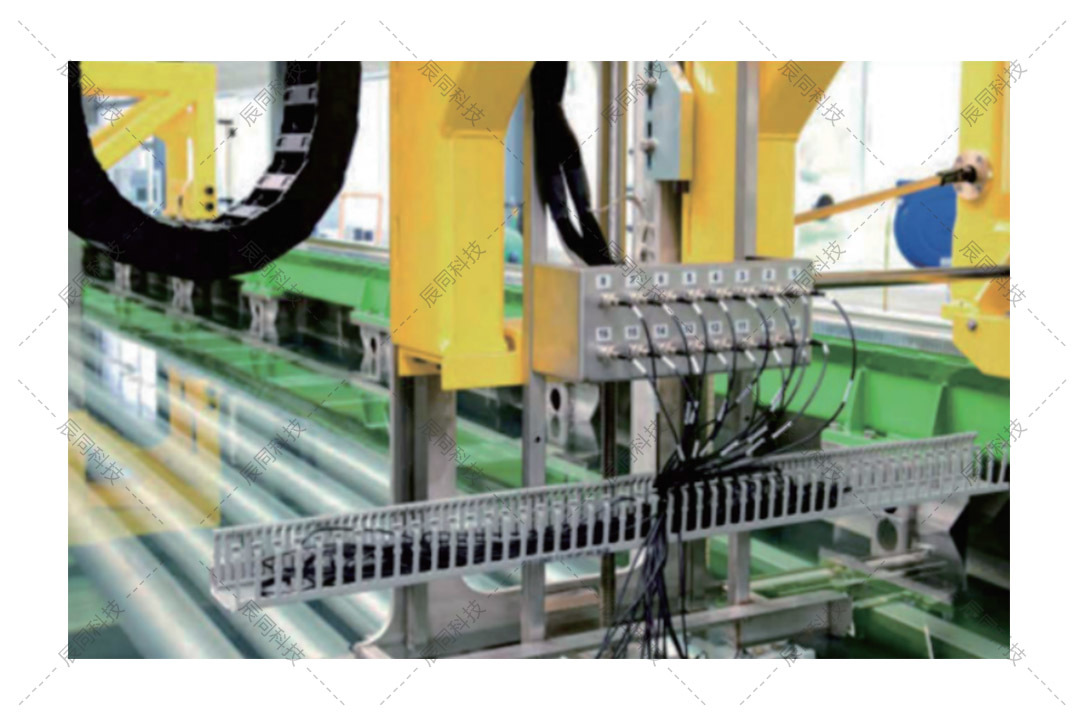

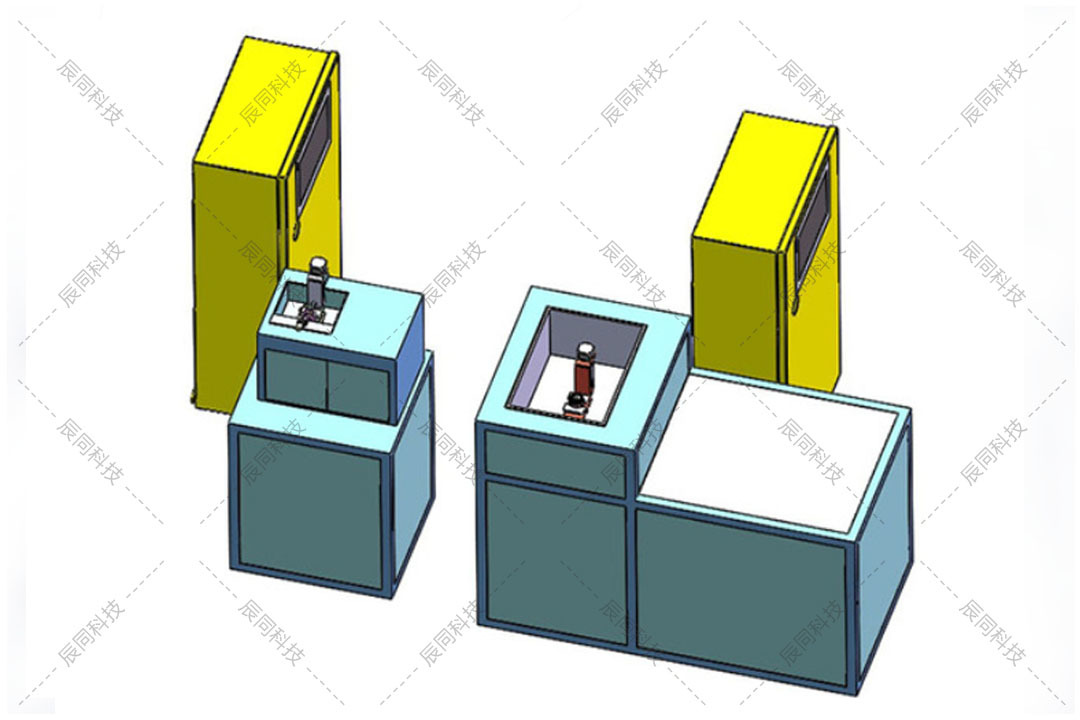

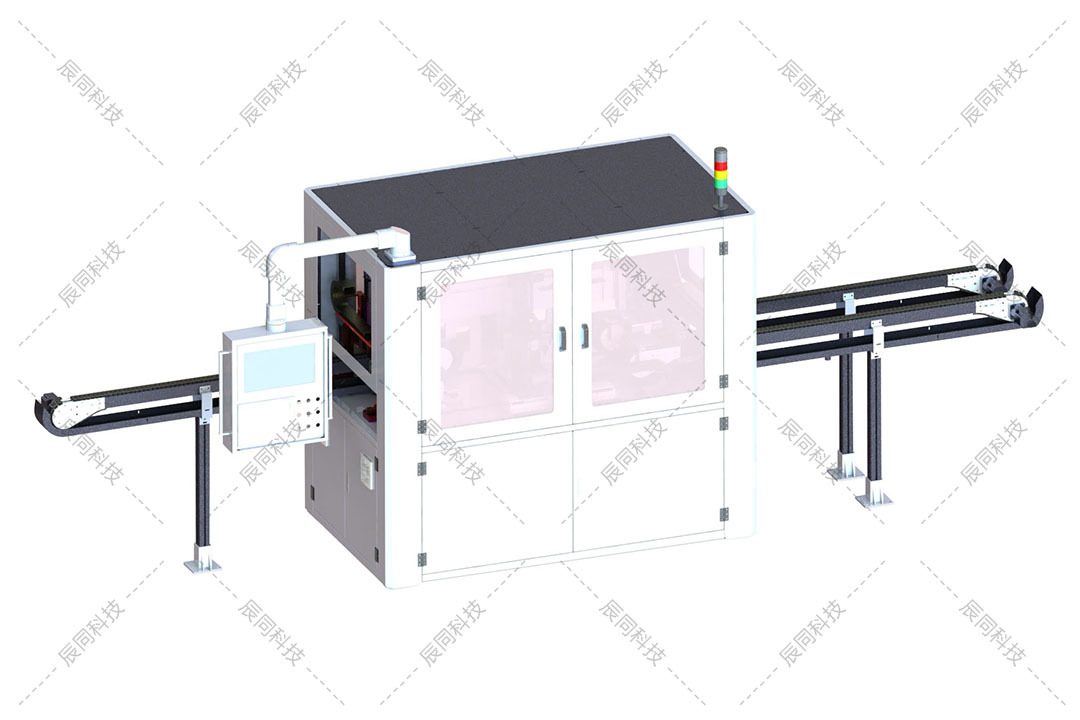

Large scale bearing ring ultrasonic testing equipment with detection sensitivity FBHΦ0.5 * 1.0mm as an artificial reference defect. The detection system adopts dual axis simultaneous detection, with 3 probes in each group. The probe control is fully automatic for adjustment. Analyze and evaluate defects by directly analyzing defect echoes or detecting the attenuation of bottom echoes.

Key words:

Ultrasonic inspection丨Visual inspection丨Automation

Product Description

- 産品描述

-

Large scale bearing ring ultrasonic testing equipment with detection sensitivity FBHΦ0.5 * 1.0mm as an artificial reference defect. The detection system adopts dual axis simultaneous detection, with 3 probes in each group. The probe control is fully automatic for adjustment. Analyze and evaluate defects by directly analyzing defect echoes or detecting the attenuation of bottom echoes.Product parameters

Equipment Model CTR3080 Dimension 10500*10500*5000mm Testing specifications Φ3000-Φ8000mm Defect Type Pores, cracks, slag, etc. Detection sensitivity FBHΦ0.5*1.0mm Detection efficiency 30-120 min/pcs Missing detection rate 0 False detection rate ≤3% Environmental requirements Temperature (5~30)℃, humidity <70% Access to power AC 380/220V,50Hz Equipment air source 0.5-0.8MPa Grounding resistance ≤2Ω Other requirements Surface cleaning of workpieces and rough machining of products Other features Real-time display of detection status

Tag:

Product inquiry