Recommend Products

Roller UT&ET testing equipment CT2060UE

Small roller eddy current and ultrasonic testing equipment with fully automatic probe mechanism adjustment to adapt to different specifications of rollers. -UT detection accuracy is FBHΦ0.5 * 1.0mm, and an oblique probe is used to detect near surface defects. The detection system uses two sets of probes. -ET detection accuracy of 0.75 * 0.05 * 0.05mm, using a dual probe working station.

Key words:

Ultrasonic inspection丨Visual inspection丨Automation

Product Description

- Product Description

-

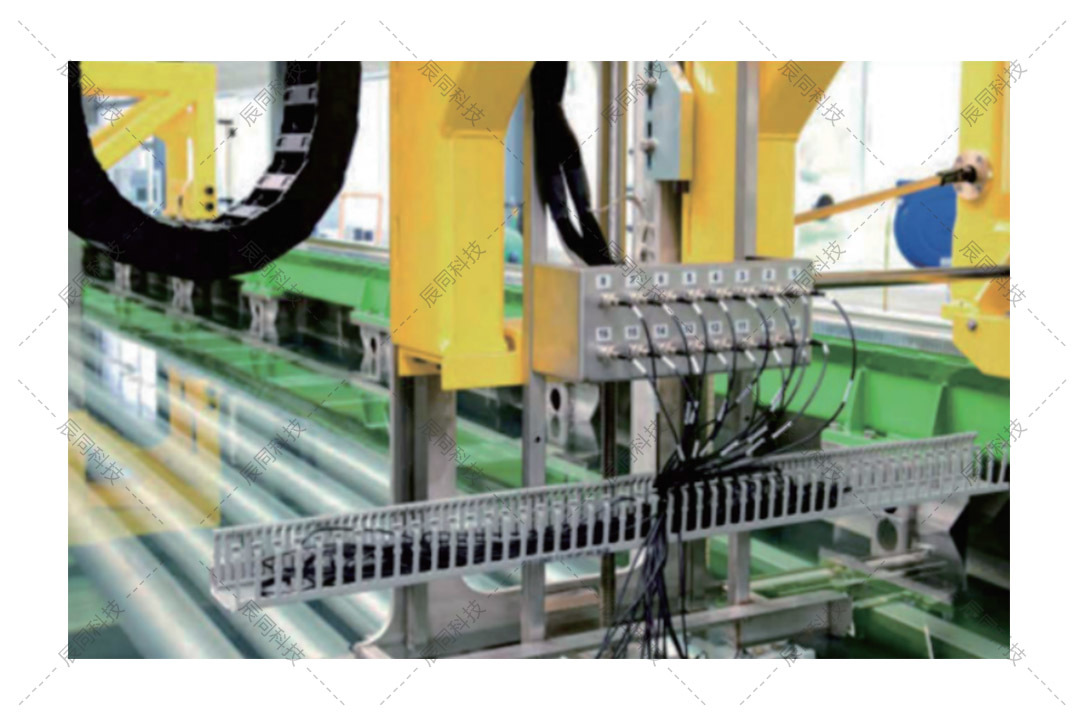

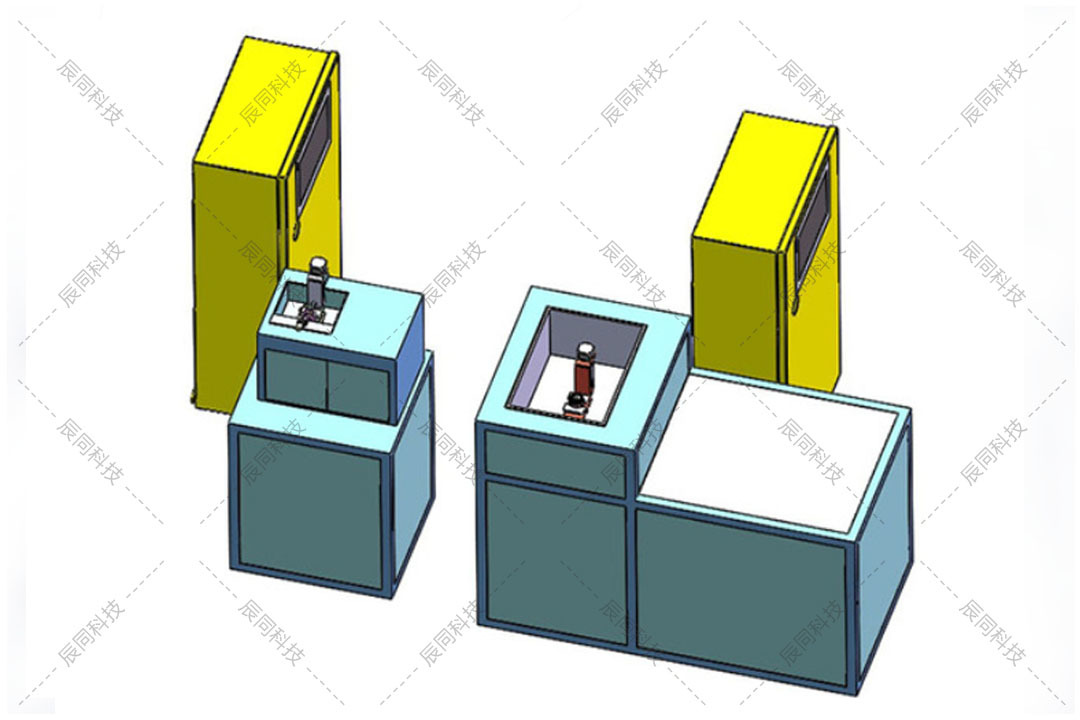

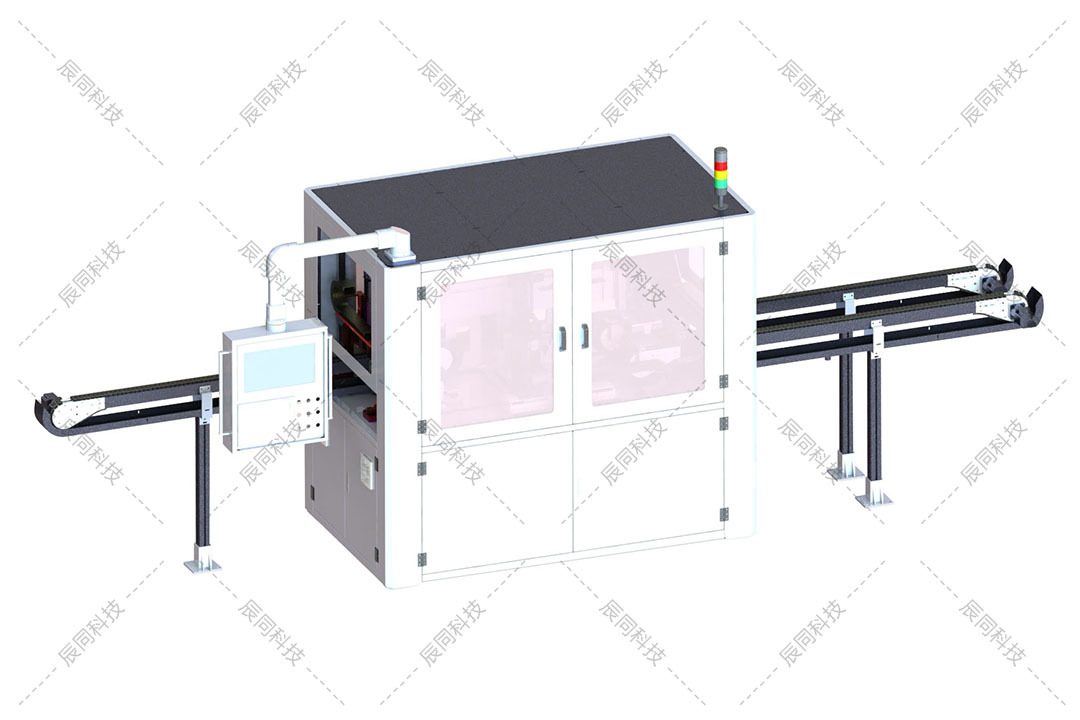

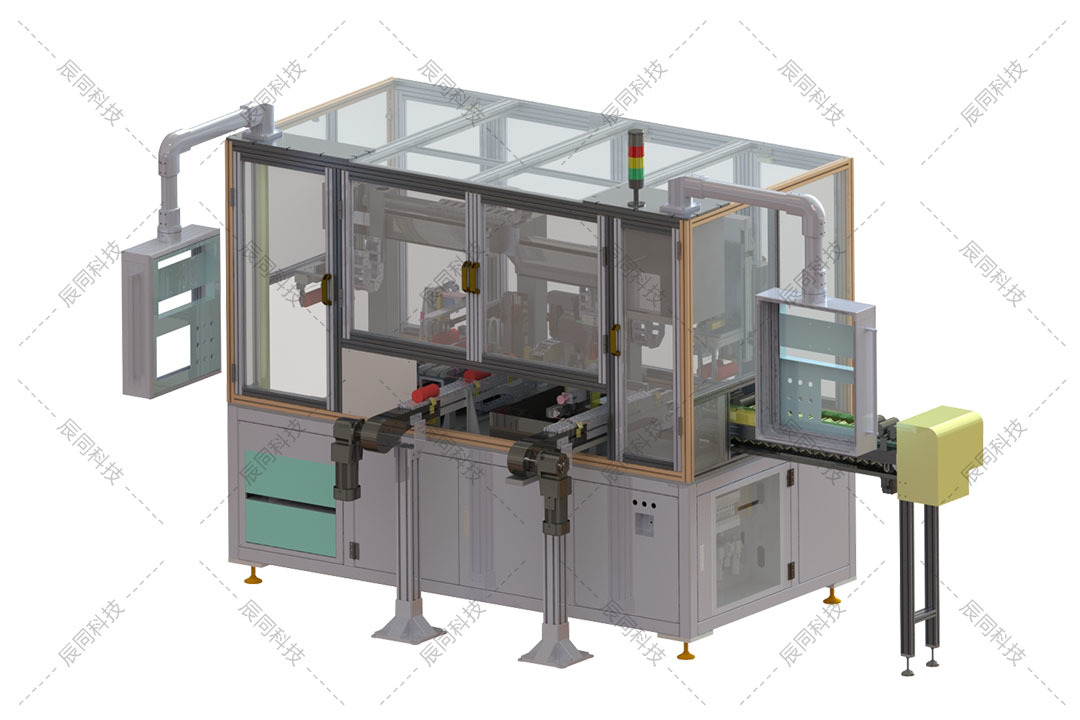

Small roller eddy current and ultrasonic testing equipment with fully automatic probe mechanism adjustment to adapt to different specifications of rollers.

-UT detection accuracy is FBHΦ0.5 * 1.0mm, and an oblique probe is used to detect near surface defects. The detection system uses two sets of probes.

-ET detection accuracy of 0.75 * 0.05 * 0.05mm, using a dual probe working station.

Product parameters

Equipment model CT2060UE Dimension 2480*1280*2050mm Testing specifications Φ40- Φ60mm Defect type Pores, cracks, slag inclusions, etc Detection sensitivity FBHΦ0.5*1.0mm、0.75*0.05*0.05mm Detection efficiency 10s/pcs Missing detection rate 0 False detection rate ≤3% Environmental requirements Temperature (5~30)℃, humidity <70% Access to power AC380/220V,50Hz Equipment air source 0.5-0.8MPa Grounding resistance ≤2Ω Other requirements Surface cleaning of workpieces and rough machining of products Other features Real-time display of detection status

Tag:

Product inquiry