Application

Application of Ultrasonic Nondestructive Testing

Visual Applications

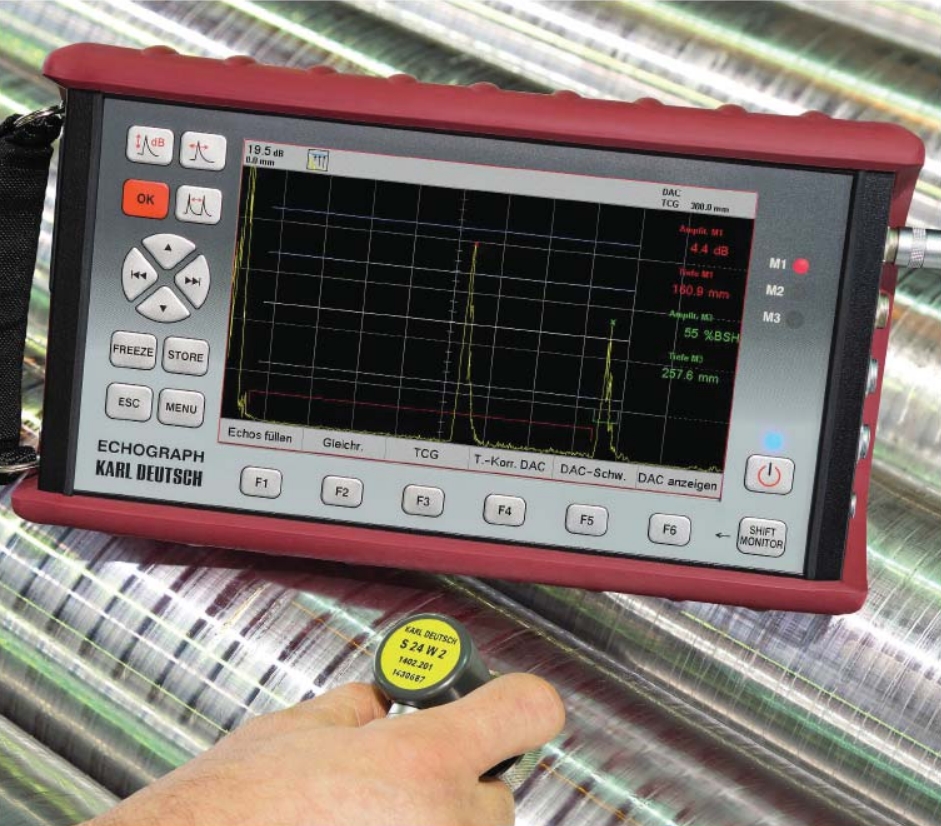

Handheld ultrasonic flaw detector

Product Description: This digital manual ultrasonic testing device is an ideal manual ultrasonic testing equipment, with advantages such as sturdy mechanical and electronic components and configurations, high contrast and high brightness large display screen, convenient and comfortable use menu, and high protection level. It can work well even in harsh operating or outdoor environments.

Optional enhanced features: strip chart and TOFD functions, need to be used together with the encoder.

When generating a line scan strip chart, the position of the corresponding amplitude is determined by the displacement encoder and transmitted digitally to the device. For weld seam detection, the TOFD method (ultrasonic diffraction time difference method) can be used, where ultrasonic waves generate diffraction signals at the edge of defects to determine their location and size.

The wall thickness measurement values can be saved in the cells of the matrix grid through array storage methods. The measurement values in the matrix grid correspond to the measurement points of the inspected parts. At the same time, the measurement values in the matrix grid are displayed in different colors, which can quickly evaluate the measurement results and perform error analysis. For example, measuring the remaining thickness of the pipeline wall after corrosion.

In the process of probe setup and equipment calibration, there are operation instructions set up, and operation support is provided for customers with insufficient operation experience: simply activate the operation assistant and follow the instructions on the screen for operation.

Main technical parameters:

· Weighing only 2 kg, suitable for handheld operation, height x width x depth: 138mm x 249mm x 52mm (without protective cover), 149mm x 262mm x 54mm (with protective cover)

· Large, high contrast TFT color display (7 inches, resolution 800 x 480 dots) with automatic adjustment of screen brightness and large viewing angle

· A concise and clear operation menu and interface allow users to operate conveniently and quickly. Operators can calibrate or draw curves (AVG, DAC, TCG, AWS, JIS, etc.) by holding detection probes

· Three gates correspond to three LED indicator lights

· Pulse repetition frequency: up to 5000 Hz

· Matrix storage

· TOFD

· B-scan

· Line scan strip chart