Recommend Products

Roller visual loading

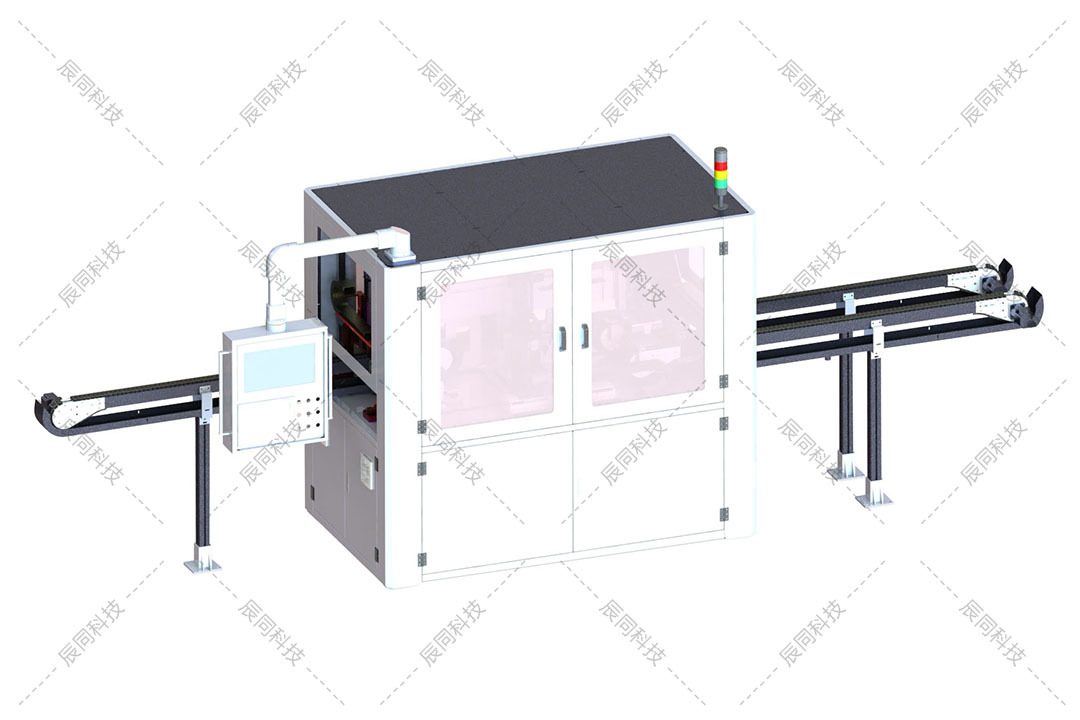

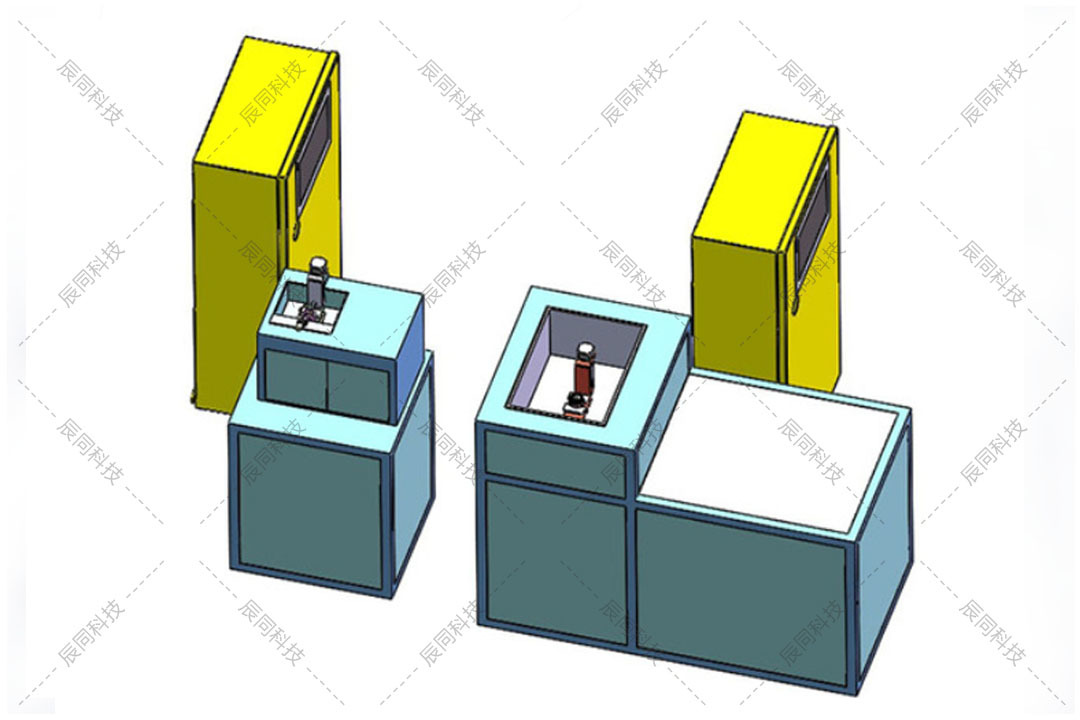

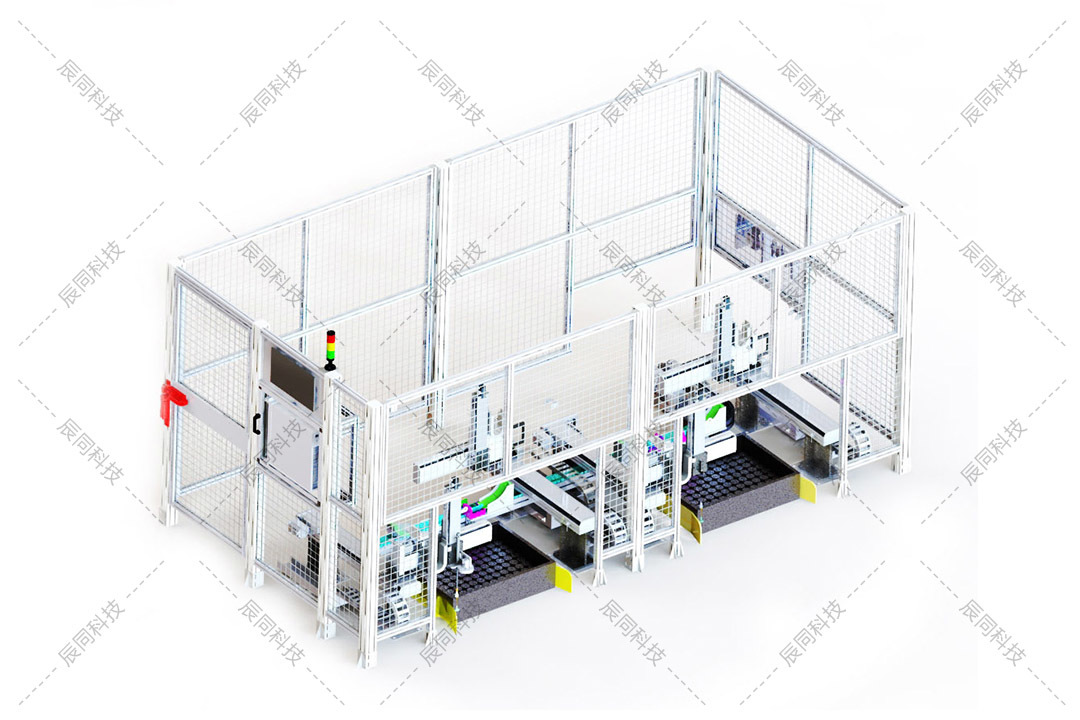

This machine is used for automatic loading of roller line, using visual positioning, double-station 3-axis module + 4 sets of suction cups. The suction cups adopt single suction cup and quick change mechanism, which is convenient for the operator to change the suction cups. The tray can put 1-3 layers of rollers, and the rollers are placed vertically.

Key words:

Ultrasonic inspection丨Visual inspection丨Automation

Product Description

- 産品描述

-

This machine is used for automatic loading of roller line, using visual positioning, double-station 3-axis module + 4 sets of suction cups. The suction cups adopt single suction cup and quick change mechanism, which is convenient for the operator to change the suction cups. The tray can put 1-3 layers of rollers, and the rollers are placed vertically.Product parameters

Function Visual grip loading Crawl Type Bearing rollers, other parts products Detection accuracy ±0.2mm Detection efficiency 3s/pcs Environmental requirements Temperature (5~30)℃ Humidity <70% Access to power AC 380/220V,50Hz Equipment air source 0.5-0.8Mpa Other requirements Surface cleaning of workpieces and rough machining of products Other features Real-time display of loading status and quantity

Tag:

Product inquiry