Recommend Products

Automatic bearing collar production line

The non-standard automation customization mainly includes bearing collar automatic production line, bearing roller automatic production line, bearing automatic assembly line, steel ball automatic packaging line, automatic loading and unloading production line, intelligent storage, optical testing equipment, etc.

Key words:

Ultrasonic inspection丨Visual inspection丨Automation

Product Description

- 産品描述

-

The non-standard automation customization mainly includes bearing collar automatic production line, bearing roller automatic production line, bearing automatic assembly line, steel ball automatic packaging line, automatic loading and unloading production line, intelligent storage, optical testing equipment, etc.

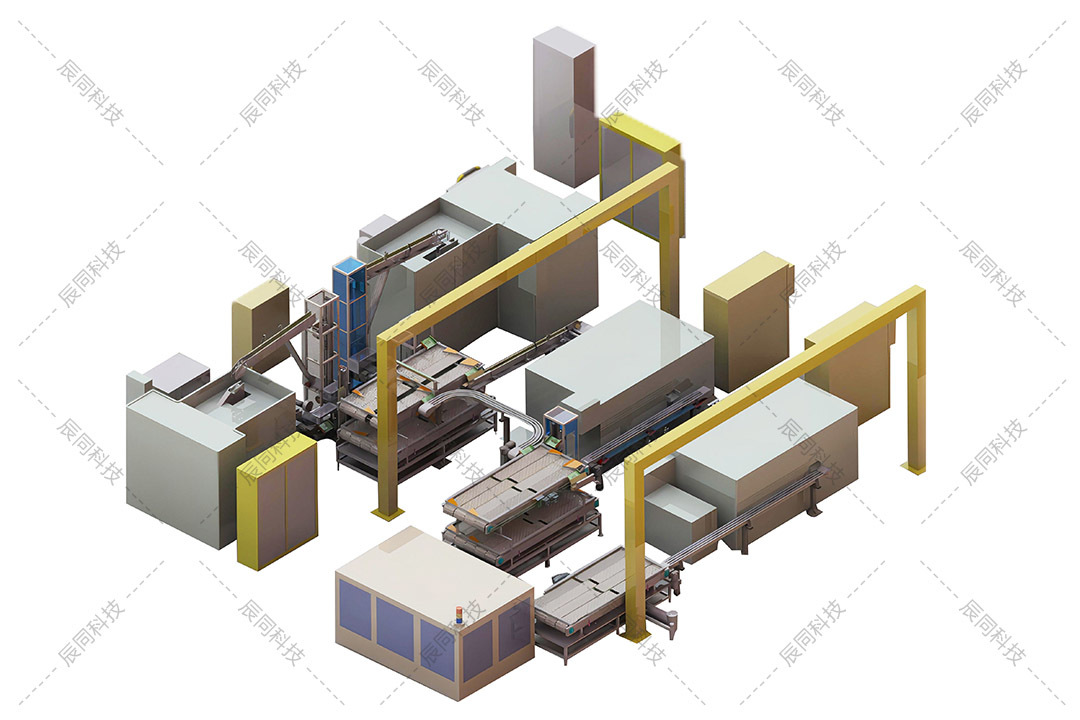

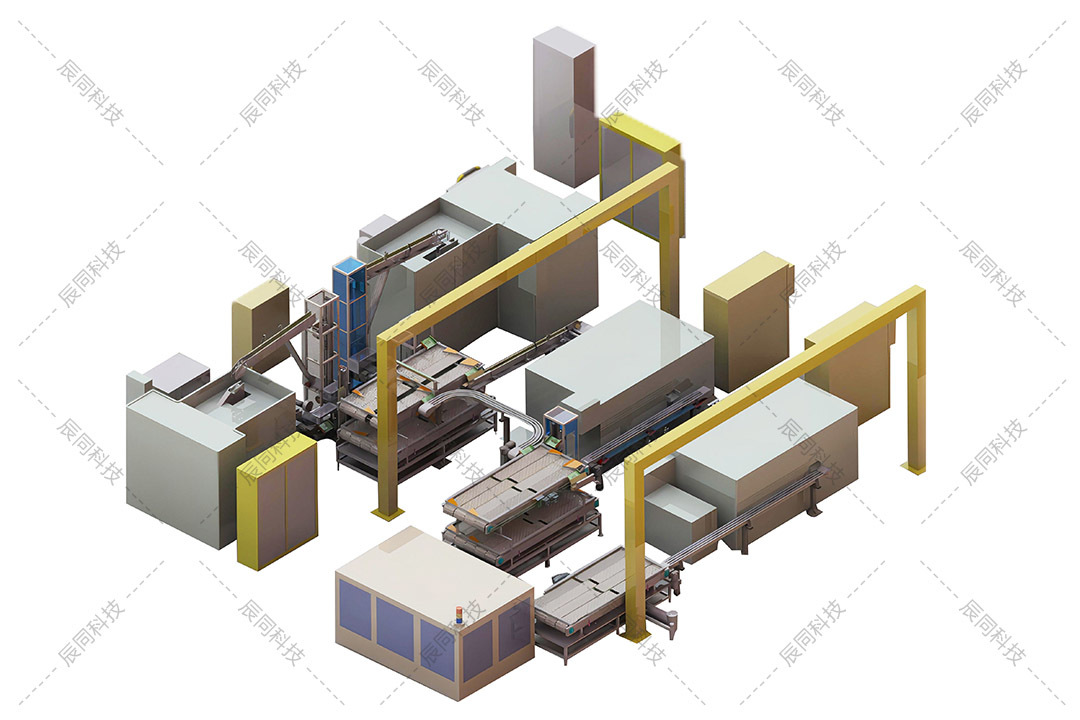

Example: Automatic bearing collar production line

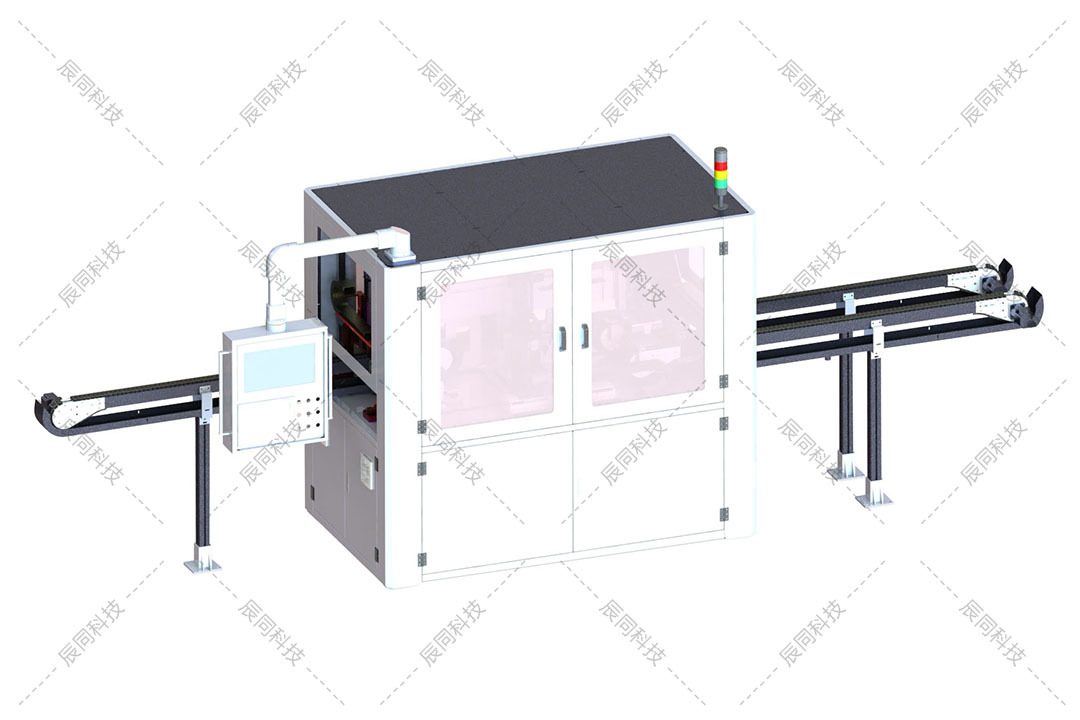

This equipment is used for the automatic production line of bearing ring grinding, which consists of 3D vision loading machine, elevator, chain plate conveying line, demagnetizing machine, and other major components, supplemented by electrical control technology and sensors to achieve closed-loop control, providing automatic loading and unloading and conveying materials for grinding machines.3D vision + robot gripping and feeding, safe and reliable, reduce personnel involvement to improve production efficiency and safety.Product protection: Non-metallic materials such as nylon or PE are used for parts in contact with the collar.

Example: Automatic bearing collar production line

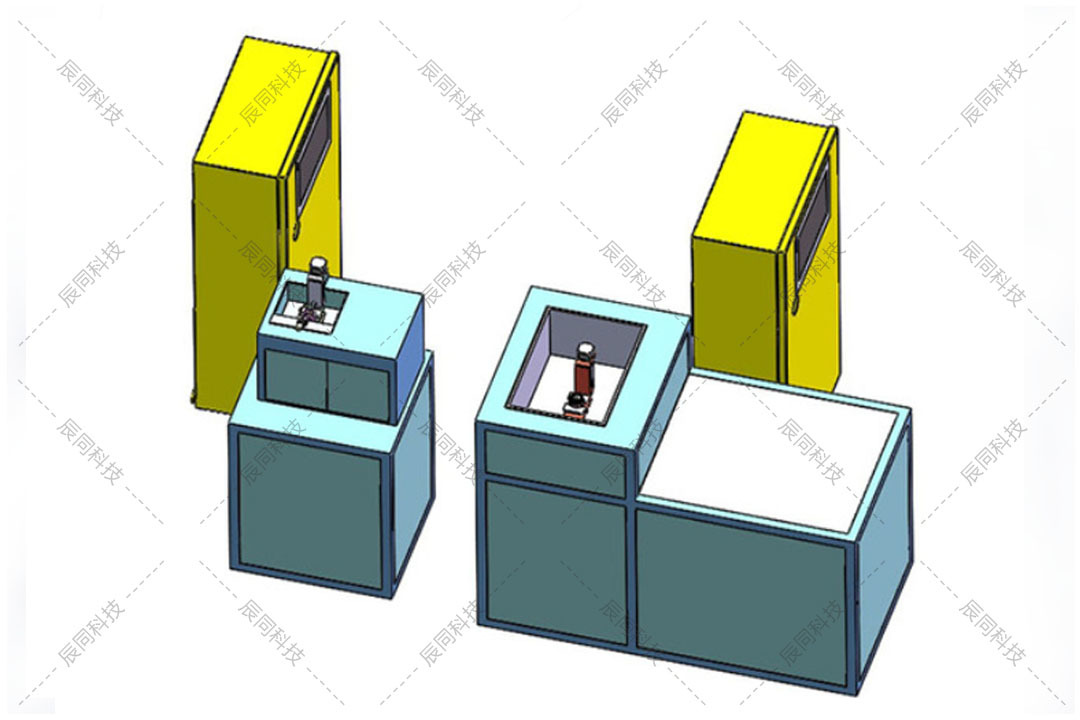

This equipment is used for steel ball anti-mixing, automatic counting, automatic packing, sealing, box lid, gluing, labeling, packing and other actions. It can reduce the manual work station, improve the accuracy of packing quantity and reduce the labor intensity of staff.Product whole line packing time: ensure that each box packing time is less than 20S, the number of steel balls per box is 1500, and the oil-proof bag is placed in the middle.Steel ball protection: Soft materials such as nylon are used in the contact position with steel balls, and suction cups are used for handling. Example: Automatic bearing assembly line

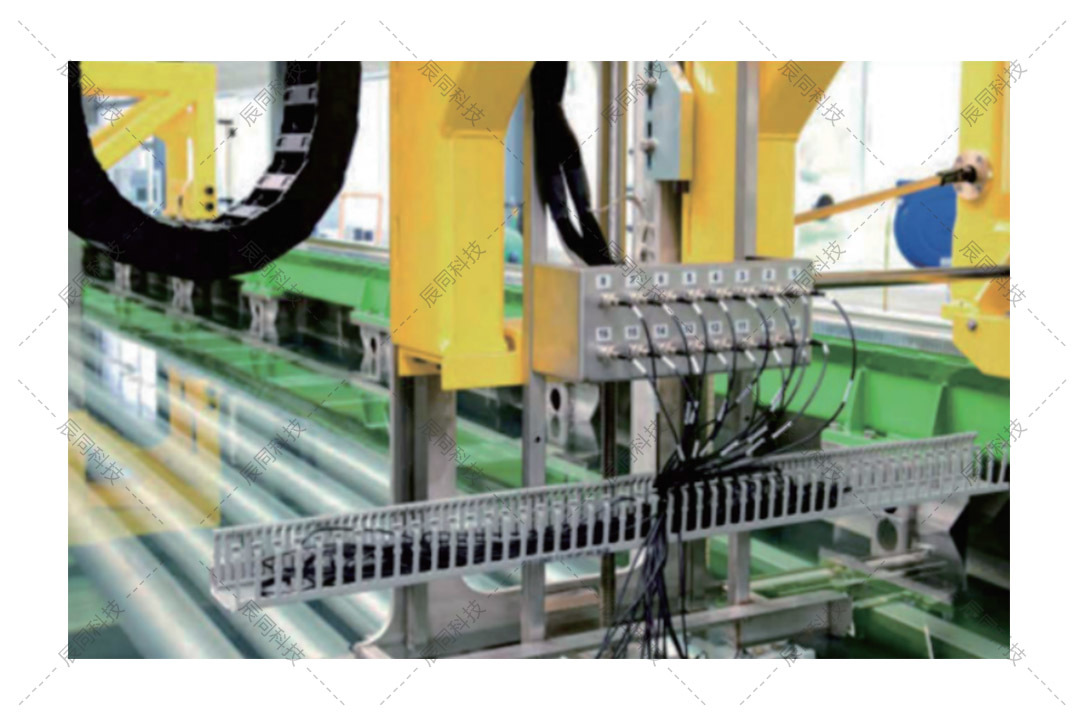

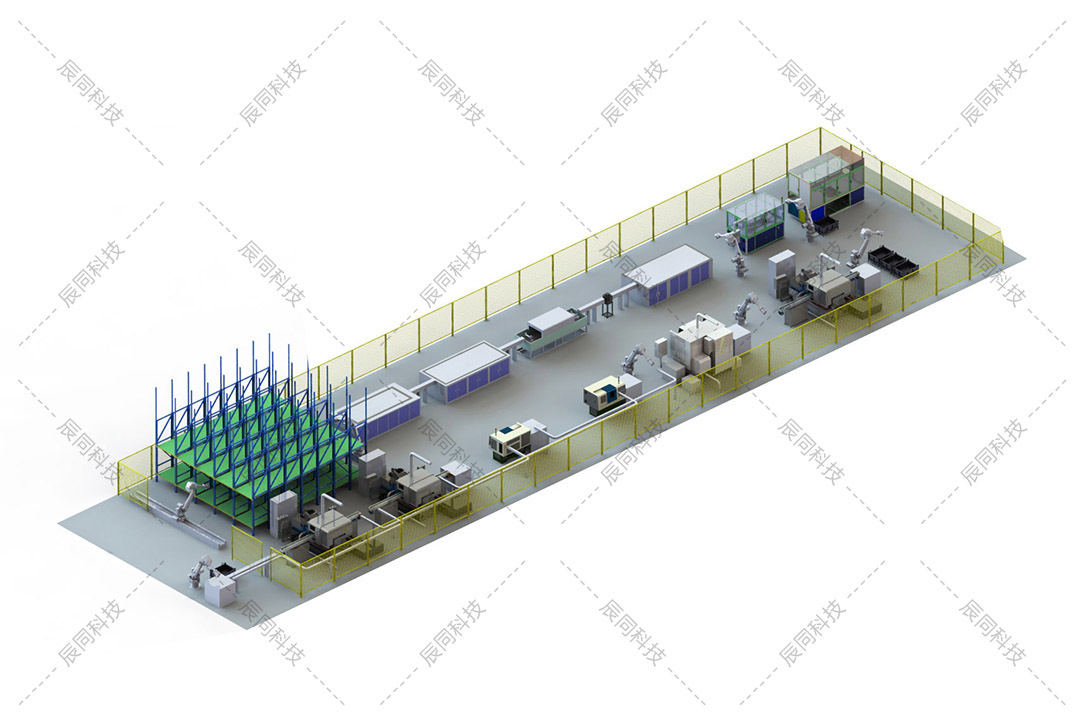

Example: Automatic bearing assembly line Example: Automatic steel ball packing lineThis equipment is used for the automatic production line of bearing ring grinding processing, which consists of main components such as caching machine, elevator, chain plate conveying line, demagnetizing machine, and downcomer caching machine, etc., supplemented by electrical control technology and sensors to achieve closed-loop control, providing automatic loading and unloading and conveying materials for grinding machines.The line can automatically switch the processing route according to the production demand, and all the adjusting mechanisms are in the personnel-operable position, which reduces the risk of high work and improves the efficiency of changeover.Product protection: Non-metallic materials such as nylon or PE are used for parts in contact with the collar.

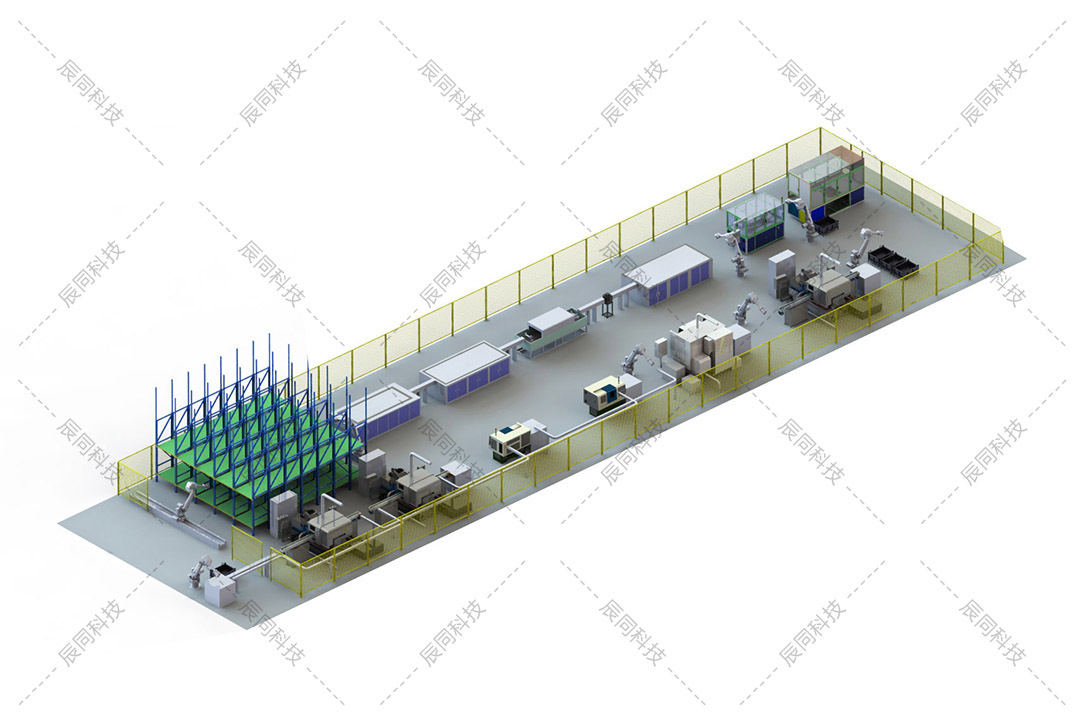

Example: Automatic steel ball packing lineThis equipment is used for the automatic production line of bearing ring grinding processing, which consists of main components such as caching machine, elevator, chain plate conveying line, demagnetizing machine, and downcomer caching machine, etc., supplemented by electrical control technology and sensors to achieve closed-loop control, providing automatic loading and unloading and conveying materials for grinding machines.The line can automatically switch the processing route according to the production demand, and all the adjusting mechanisms are in the personnel-operable position, which reduces the risk of high work and improves the efficiency of changeover.Product protection: Non-metallic materials such as nylon or PE are used for parts in contact with the collar. Example: Fully automatic bearing ring processing lineThis equipment is used for the automatic production line of bearing ring grinding, which is composed of the main components such as loading cache, elevator, chain plate conveying line, demagnetizer, and downfeed cache, etc. It is supplemented by electrical control technology and sensors to achieve closed-loop control, providing automatic loading and unloading and conveying materials for grinding machines.The one-touch change function of the loading cache can cover a wide range of specifications and models, reducing the intensity of staff operations and improving production efficiency and safety.Product protection: Non-metallic materials such as nylon or PE are used for parts in contact with the collar.

Example: Fully automatic bearing ring processing lineThis equipment is used for the automatic production line of bearing ring grinding, which is composed of the main components such as loading cache, elevator, chain plate conveying line, demagnetizer, and downfeed cache, etc. It is supplemented by electrical control technology and sensors to achieve closed-loop control, providing automatic loading and unloading and conveying materials for grinding machines.The one-touch change function of the loading cache can cover a wide range of specifications and models, reducing the intensity of staff operations and improving production efficiency and safety.Product protection: Non-metallic materials such as nylon or PE are used for parts in contact with the collar. Example: Fully automatic bearing ring processing line

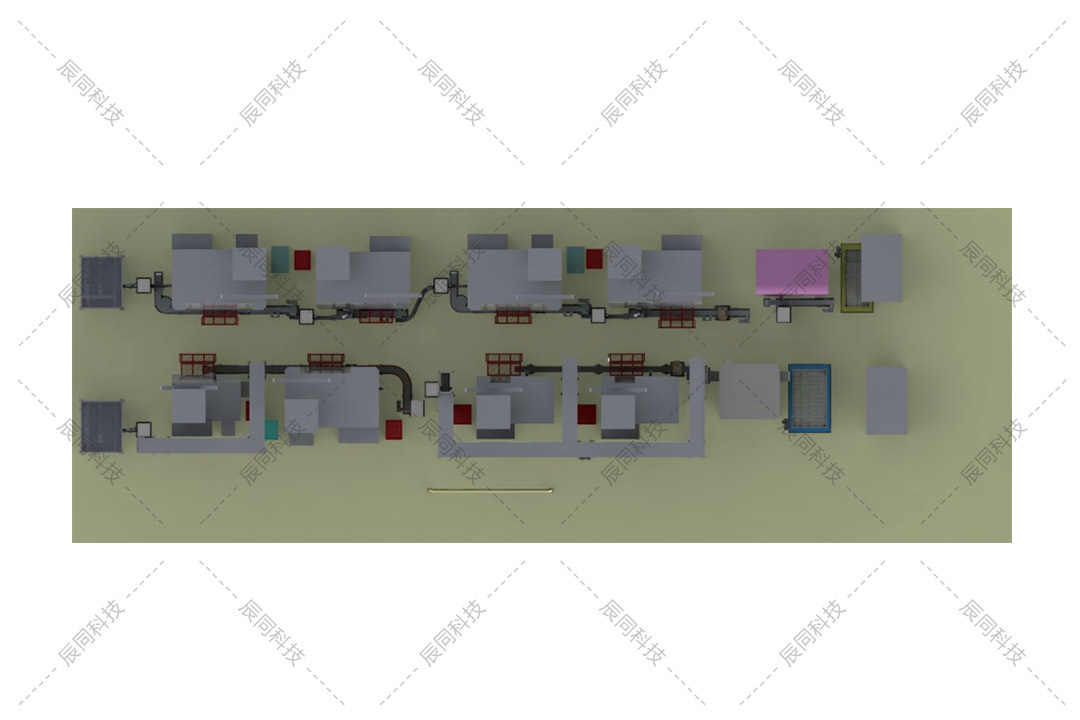

Example: Fully automatic bearing ring processing line Example: Fully automatic bearing ring processing line - top view

Example: Fully automatic bearing ring processing line - top view

Tag:

Product inquiry